Dry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

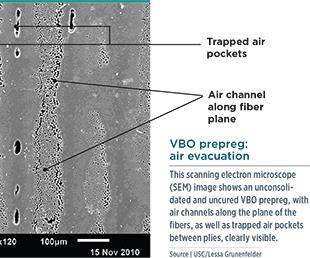

Automated dry fiber placement (DFP) and out-of-autoclave processes are listed as the key parameters that will affect the cost of future aerospace composites in the 2015 report, “Carbon composites are becoming competitive and cost effective,” produced by Infosys (Bangalore, India). Dry fiber placement removes from the manufacturing equation the additional cost of prepregging, frozen storage and autoclave processing. It also facilitates production of large unitized structures because there are no out-time limitations for complex layups as there are with prepreg. The current maximum out-time for OOA prepreg is 21 days. This could present difficulties for large, integrated wing structures, like those developed for the Irkut (Moscow, Russia) MS-21. Conversely, without this limit, it is now possible to develop unitized primary structures even further, including the use of novel materials and elements for integration of additional functions (see “Resin-infused MS-21 wings and wingbox,” under "Editor's Picks," at top right).

Because the dry fibers are infused or injected with liquid resin after layup, the dry fiber tows must be coated with a binder to prevent displacement during automated layup.

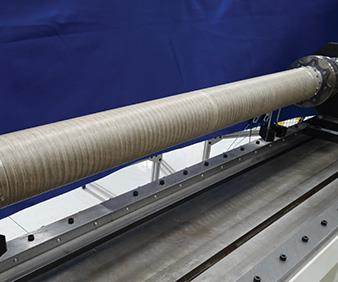

How does automated fiber placement (AFP) with dry fiber differ from traditional epoxy prepreg tows? “It is less stiff, so you must keep the fiber tension in the machine very low,” replies Coriolis Composites SAS (Queven, France) chief technology officer Alexandre Hamlyn. He notes this makes laying fiber at high speeds more challenging than with thermoset materials and that accuracy of fiber placement is also demanding. “You must optimize the fiber placement to achieve permeability in the preform so that it can be infused reliably,” Hamlyn adds. However, he notes that early indications from development work, to date, show dry fiber-placed/liquid resin-infused structures have improved mechanical properties. Why? Although work is still ongoing, Hamlyn says the thermoplastic binder on the fibers improves toughness, which then impacts the failure mode for other properties.

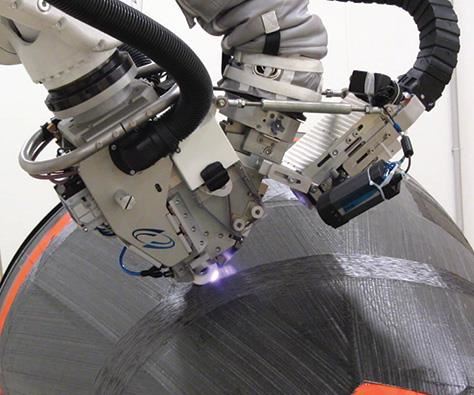

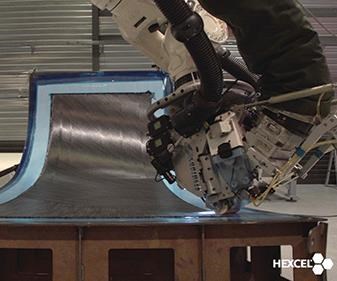

Coriolis refined its robotic dry-fiber placement machines to make laser heating standard during the 2009-2013 ADVITAC project, which sought to produce a smart composite aircraft tailcone via a fastener-free, integrated structure, using dry fiber placement and liquid resin molding. It also worked with composite parts manufacturer Aerocomposit (Moscow, Russia) to adapt this technology for the resin-infused wing on the MS-21 single-aisle jetliner.

A robot-based Coriolis machine is now producing wing spar and stringer preforms at Aerocomposit, while a gantry-based machine by MTorres(Torres de Elorz, Spain) is laying up the wingskin preforms. “The robot is well-adapted for complicated shapes,” explains Hamlyn. “It is also very dynamic, which is important because it must interpolate up to eight axes of movement at a time, including that of the tool supporting the structures. This is part of the software we have developed to optimize the machine’s performance.”

Hamlyn notes that the Coriolis machines can place dry fiber at the same speed as conventional AFP, “but this is partly because all of our machines have been developed to handle dry fiber as well as thermoset and thermoplastic prepreg materials.” He explains that when Coriolis was founded in 2000, its initial targets were wind blades and automotive parts, applications that require low-cost materials, such as dry fiber. Coriolis switched to thermoset tapes only when it began working with Airbus (Toulouse, France), because the OEM wanted to use already qualified materials. “But we realized that one day the aerospace industry would want to use dry fiber as well,” says Hamlyn.

Indeed, many projects and players are pursuing dry fiber placement for both aerospace and automotive/transportation applications (see the Side Story below).

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreThe making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreRead Next

Research on OOA processing continues

Much work has been done to make OOA processing practical for aerospace applications, but much work still remains if it is to become the compelling option.

Read MoreOOA: Thermoplastic alternative targets performance spec

CF/PEEK helicopter driveshaft’s toughness trumps traditional metric.

Read More