All hail SMC

Sheet molding compound (SMC) is no stranger to the composites industry, but the last few years have seen a renaissance for this workhorse material as it is embraced anew.

A. Schulman Inc./Quantum Composites offers three grades of SMC:

Grade 8575, Grade 8585 and Grade 8595. Tensile modulus ranges from

33,090 MPa to 99,300 MPa.

Sheet molding compound (SMC) is no stranger to the composites industry, with a long and illustrious history in everything from cars and trucks to recreational vehicles and industrial structures. The last few years, however, have seen a renaissance for this workhorse material as it is embraced anew.

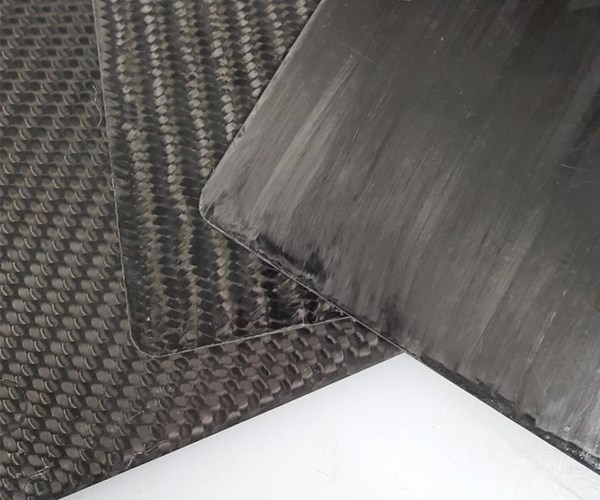

New high-strength SMCs with specific gravity (SG) hovering around 1.0 now have their sights set on aluminum in automotive body panels and other structures, and carbon fiber and epoxy are now also in the material mix from some suppliers.

CW contributor Peggy Malnati walks you through the state of the SMC art with a two-part series that explores SMC’s capabilities and how the material is being used today:

- SMC: Old dog, new tricks: Looks at the fibers, chemistries, fillers and resin matrices that define today’s SMCs, and what they can do.

- SMC: Old dog, more tricks: Reviews the use of polyurethane in SMC, new work on sizing chemistry, loc-VOC resin formulations and low- or no-styrene options.

SMC has a long history of use in vehicles like this one.

The universe of applications is getting bigger.

Related Content

-

Protecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

.jpg;maxWidth=300;quality=90)