Composite 3D printing is often used for tooling and prototypes, but companies like Dive Technologies and Moi Composites are demonstrating that additive manufacturing (AM) can help solve challenges in short-run and one-off end-use part production within the marine industry. One example is Dive’s 3D-printed autonomous underwater vehicle (pictured). Photo Credit: Dive Technologies

The ability to quickly build different iterations of parts — without having to develop or purchase costly dedicated tooling — is why additive manufacturing (AM) is so often used in part prototyping. However, as materials and printing technologies continue to improve, more companies are able to extend AM’s speed and versatility into end-use parts as well, particularly for short-run or one-off applications where the ability to quickly produce new designs is an asset.

Recently, two companies have demonstrated that composite AM technologies can be enabling solutions for customizing large marine structures such as autonomous underwater vehicles (AUV) and motorboats.

Large-format 3D printing for customizable AUV production

Autonomous underwater vehicles are a type of unmanned robotic vehicle capable of traveling underwater without physical connection to a boat or remote control from a human operator, and are often outfitted with cameras or sensors for various use cases in defense, ocean research or offshore survey applications. Typically, the exterior hulls of AUVs either comprise one big metal pressure vessel, or they’re built from thermoformed plastic or composites. Both options, however, require the development and purchase of dedicated tooling, which can be expensive and limits the amount of customization that can be accommodated for AUV customers. AUV manufacturer Dive Technologies (Quincy, Mass., U.S.) has discovered that composite 3D printing solves many of the limitations of traditional manufacturing.

In 2018, Dive Technologies co-founders Bill Lebo, Jerry Sgobbo and Sam Russo decided to form their own company to design and launch a new, more capable AUV that meets customer demands for long endurance and large payload capacity.

Each of the fiber-filled ABS fairings is additively manufactured using one of Additive Engineering Solutions’ BAAM printers. Photo Credit: AES

What they and their team developed is the DIVE-LD, a 19-foot-long, 4-foot-diameter commercial AUV capable of diving to 6,000 meters and traveling up to 500 miles, carrying a payload of up to 1 cubic meter. Originally the team assumed that the final structure for its vehicle would use thermoformed plastics for the outer hull. To explore and test the design, Dive Technologies talked to Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) about the use of 3D printing for rapid prototyping. Through ORNL, the Dive team was introduced to large-format additive manufacturing (LFAM) specialist Additive Engineering Solutions (AES, Akron, Ohio, U.S.), and began working with the AES team on a manufacturing process for its AUV hull forms.

Over the course of working on the 3D-printed prototypes, however, Dive Technologies realized the potential for LFAM to rapidly produce finished components, not just prototypes. Not only did the 3D-printed prototype components meet part requirements better than expected, but adopting AM for production vehicles would also save tooling costs, allow Dive to produce end products faster than using traditional methods and enable a new, higher level of rapid customization for customers.

The exterior of Dive Technologies’ 19-foot-long DIVE-LD autonomous underwater vehicle is manufactured from nine 3D-printed composite fairings that are mechanically assembled and coated. Photo Credit: Dive Technologies

The DIVE-LD’s exterior hull comprises nine tube-shaped fairings printed using one of AES’ four Cincinnati Inc. (Cincinnati, Ohio, U.S.) Big Area Additive Manufacturing (BAAM) 3D printers. These fairings are printed from chopped fiber-filled ABS supplied by Sabic (Riyadh, Saudi Arabia). According to AES’ co-founder and VP, Andrew Bader, AES can print all of the parts for a complete hull in less than two days. Once delivered to Dive, the 3D-printed fairings are mechanically fastened using four fasteners per fairing, and coated to produce a smooth, hydrodynamic exterior surface. Following successful initial testing in 2020, Dive is building the first customer vehicles this spring and will deliver the first order in June 2021.

According to Russo, AM has become a core part of Dive Technologies’ value proposition for future vehicles and products. The partnership with Dive is a big step for AES and composite 3D printing, as well. Bader adds: “Usually when people think of 3D printing, they think of prototypes, fixtures and tooling, so this shows what else 3D printing is capable of.”

To read more about Dive Technologies and AES, read “Large-format 3D printing enables toolless, rapid production for AUVs.”

Continuous fiber AM and automation for versatile motorboat design

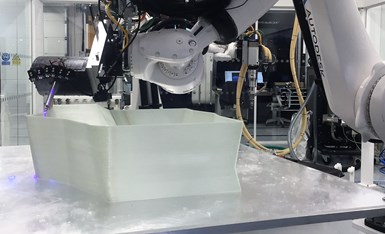

Since patenting its continuous fiber manufacturing (CFM) process in 2015, Moi Composites (Milan, Italy) has explored a range of applications for its deposition-based, continuous-fiber 3D printing CFM technology. Hallmarks of CFM include Moi Composites’ custom design software, the use of robotic arms, UV cure and “hybrid” manufacturing — more traditional composite lamination on top of a 3D-printed structural core. Recently, the company has demonstrated its CFM technology as a solution for more cost-effective, faster and more innovative marine structures design, through a demonstrator motorboat called MAMBO.

Moi Composites’ CFM technology employs robotics, continuous fiber, and UV cure for high-strength 3D-printed composites. Photo Credit: Moi Composites

According to Gabriele Natale, co-founder of Moi Composites, he and fellow co-founder Michele Tonizzo attended the Genoa Boat Show in 2017 and realized that tooling costs and traditional fiberglass infusion processes used for many boat hulls limit boat designers’ ability to explore new and more complex designs. Recognizing that their moldless, continuous fiber 3D printing technology could be an enabling solution, Natale says, “From there, we started to develop a plan, and began to meet with partners within the marine industry.”

The resulting MAMBO boat is 6.5 meters long x 2.5 meters wide, with a dry weight of approximately 800 kilograms, equipped with a navigation system, cork flooring, white leather seats and 115 horsepower engine. Moi Composites worked with marine design engineering studio MICAD (Lecce, Italy) on the structural design concept for the boat, which combines organic shapes into its structural elements inspired by the famous Arcidiavolo catamaran by Sonny Levi. Autodesk (San Rafael, Calif., U.S.) Fusion 360 CAD and NETFABB additive manufacturing software were used in the design and fluid dynamic analysis of the components.

The hull and deck of the boat, printed from unidirectional E-glass supplied by Owens Corning (Toledo, Ohio, U.S.) and vinyl ester resin, were designed to be manufactured in 50 individual sections of varying sizes. Half of the sections were printed at Moi Composites’ Milan facility, and the other half at partner Autodesk’s Advanced Manufacturing Facility (ACF) in Birmingham, U.K. Moi Composites’ CFM 3D printing technology and dual Kuka (Augsburg, Germany) robots were used at both facilities. According to Dominique Müller, research manager on the additive manufacturing team at Autodesk, the CFM system at Autodesk’s technology center allowed the boat to be printed quickly, and also enabled the Autodesk to better get to know the technology that Moi was driving remotely using Autodesk software. Total print time for all components was approximately two months.

The 50 individual components of MAMBO were assembled and bonded at Catmarine shipyard. Photo Credit: Moi Composites

The printed parts were shipped to Catmarine shipyard in Miggiano, Italy, where they were pieced together and adhesively bonded. In a hybrid manufacturing process similar to what Moi has used with prosthetics and other parts, entire hull was then laminated via hand layup with an additional fiberglass/polyester layer cored with PVC foam, which, Natale says varies in thickness along the structure. After the hull and deck were fully assembled, sanded and gel-coated, Moi Composites’ partners outfitted the boat with propulsion, navigation and other systems to complete the boat.

Initial sea trials and stability tests were performed in fall 2020, with MAMBO reaching up to 26 knots; Moi Composites plans to continue sea trials in summer 2021 working toward certification of the boat.

The 6.5-meter-long MAMBO demonstrator boat is printed from unidirectional glass fiber, with an additional fiberglass layer hand-laminated over the top for structural continuity. Photo Credit: Moi Composites

“Additive manufacturing, digitalization and automation can speed up the creation of new concepts and futuristic projects, because for each boat you want to design, you need to create a new mold. Using this technology, you can easily modify your 3D model and print it again. This is perfect especially for short-run or one-off boats,” Natale says.

For more on MAMBO, read “MAMBO tests the waters for 3D printing large marine structures.”

Related Content

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreRead Next

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;width=70;height=70;mode=crop)