Thermoplastics

KVE Composites installs first commercial Mobile Induction Welding Cell (MIWC) at Daher

Flexible welding cell developed for coupon welding to facilitate process qualification of KVE INDUCT welding technology for thermoplastic composites.

Read MoreCosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

WatchXlynX Materials releases new polymer molecular glue: BondLynx

"Hyper glue" adhesive forges new bonds at the molecular level to permanently adhere difficult-to-bond polymers.

Read MoreDLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

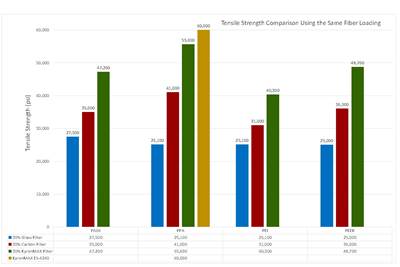

Read MoreShort carbon fiber compounds expand reach of thermoplastic composites

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Read MoreHexcel signs long-term manufacturing contract with Boeing

Hexcel will produce HexPEKK-100 manufactured-to-print aerospace structures, including various air flow ducting applications and other supporting elements, for the Boeing 777X.

Read More9T Labs recognized as a Swiss Top 100 Startup company

9T Labs has been awarded third place in the 2021 Swiss Top 100 Startups competition for its hybrid 3D printing technology, which combines 3D printing with compression molding in matched metal dies.

Read MoreSolvay completes South Carolina facility installation, adds to U.S. thermoplastic composite capacity

Facility development is fueled by increasing energy, aerospace and automotive demand, and will manufacture UD PVDF, PPS and PEEK tapes.

Read MoreSuprem expands thermoplastic capabilities

A tailored combination of fiber reinforcement and high-performance thermoplastics can now be processed with this technology to fulfill applications from marine to aerospace.

Read MoreSalewa's new hiking boot features thermoplastic composites

The Ortles Couloir boot includes thermoplastic composites from Xenia Materials and was designed to offer both stiffness and flexibility.

Read More