RTM

CAMX 2021: Cimbar Performance Materials

Cimbar Performance Materials’ halogen-free ATH solution for thermoset applications reduces resin costs in formulation, provides better wetout and faster line speeds and improves mold flow.

Read MoreCAMX 2021 exhibit preview: Scott Bader

Scott Bader displays its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling system.

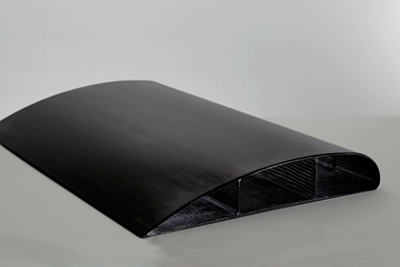

Read MoreCAMX 2021 exhibit preview: Hawthorn Composites

Hawthorn showcases its co-cured wing structure that was made using dry carbon fiber application, overbraiding, liquid infusion and its Smart Tooling.

Read MoreAltair's 9th Enlighten Award winners feature vehicle lightweighting, sustainability

Annual award honors advancements in reducing the carbon footprint, mitigating water and energy consumption, promoting material reuse and recycling and applying composites for lightweighting.

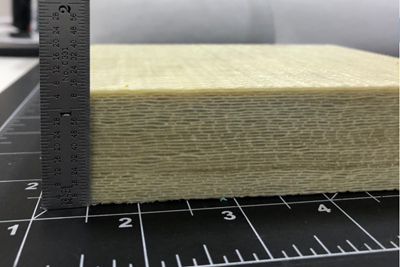

Read MoreHexPly M901 prepreg accelerates product development cycles

Hexcel’s HexPly M901 prepreg system reportedly reduces production time of composite leaf springs.

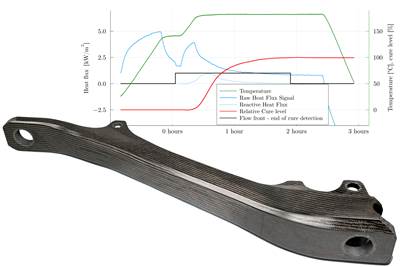

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read MoreComposites Integration expands Metyx partnership, appoints as U.S. distributor

Strengthened partnership expands RTM, infusion and technical textile offerings to U.S. markets.

Read MoreHexion partners with Rassini for composite leaf spring application in new Ford F-150 model

Pickup truck model’s hybrid rear suspension is supported by a composite helper spring which uses Hexion’s epoxy resin system and is processed via HP-RTM.

Read MoreNew thermoset matrix resin offers fast, low-temp, tunable cure

HARP Rapid is a new thermoset resin chemistry for liquid molding processes that offers a fast, tunable cure profile, and a Tg that exceeds the material’s cure temperature.

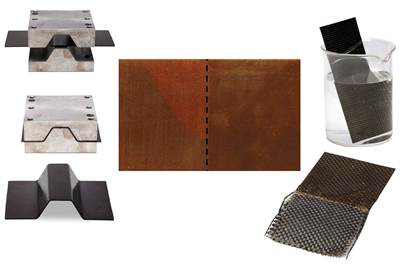

Read MoreReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

Watch