RTM

Composites in Class A body panels: Evolution continues

Low-density SMCs lead the way as fiber-reinforced polymers make headway in auto components that must please the eye.

Read MoreCW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

Read MoreRecyclable epoxy proven in HP-RTM

Recyclamine hardener performs well in global processing trials and cradle-to-cradle recycling demo.

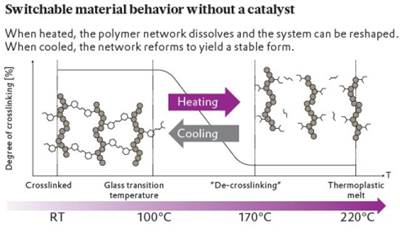

Read MoreReversibly crosslinking thermoset-thermoplastic hybrid polymers

Evonik’s new system delivers crosslinked performance of epoxies below 100°C, processing benefits of thermoplastics above 170°C.

Read MoreFalcons advance bizjet state of the art

Falcon jets are produced by Dassault Aviation (Paris, France) in Saint-Cloud and Bordeaux, with final assembly at the Bordeaux-Mérignac plant.

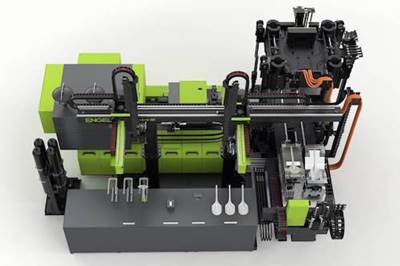

Read MoreEngel to present pre-series production solutions at Composites Europe

In partnership with Schöfer, Engel has developed a pre-series manufacturing cell for the manufacture of thermoplastic fiber-reinforced components using the in-situ polymerization technology.

Read MoreMust-read: BMW 7 Series plant tour in Dingolfing, Germany

CW’s Ginger Gardiner toured the 7 series plant for a look at how 16 CFRP parts, each made by one of four technologies, are combined with aluminum and steel components to form what BMW engineers have dubbed the Carbon Core.

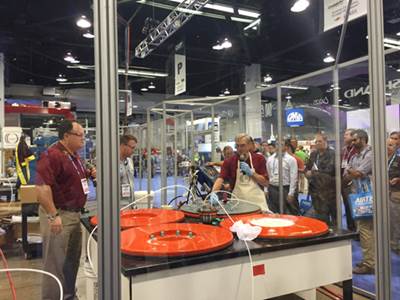

Read MoreCAMX 2016: The final report

With CAMX 2016 quickly receding, we offer this the full, complete and final report on what was seen, what was heard and what was new at North America's largest composites industry event. And we hope to see you next year at CAMX 2017, Sept. 11-14 in Orlando, Florida.

Read MoreInnovation: Moving faster than ever

The rate of composites innovation is higher than I’ve ever seen, and the implications are significant.

Read MoreCAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

Read More

.jpg;maxWidth=300;quality=90)