RTM

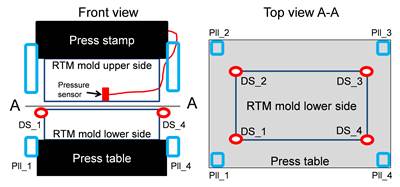

Fraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

Read MoreReconfigurable tooling: Revolutionizing composites manufacturing

Shape-changing molds eliminate tooling for large 3D panels while automated assembly fixtures go modular, using metrology to reduce cost and shimming.

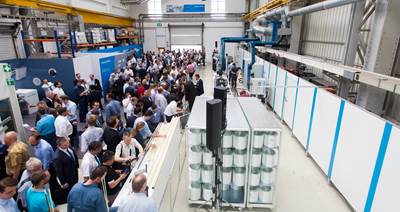

Read MoreKraussMaffei doubles pultrusion speed and continued developing composites processes for large series production

New iPul pultrusion system doubles production speed while intelligent automation cuts cycle time in FiberForm and RTM processes.

Read MorePlant Tour: Fraunhofer ICT, Pfinztal, Germany

This wide-ranging research center works with government and industry to develop the best of polymer composite processing, across a range of technologies.

Read MoreCAMX 2017 show preview

At North America’s premier composites conference and exhibition, the business at hand is definitely not business as usual.

Read MoreCAMX 2017 preview: Siempelkamp

Composites machinery specialist Siempelkamp (Krefeld, Germany) is featuring its compression equipment for sheet molding compound (SMC), phase change material (PCM), resin transfer molding (RTM) and thermoplast forming.

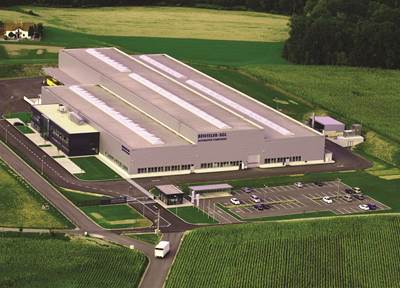

Read MoreA look inside Fraunhofer ICT

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, with more than 67 institutes and research units located throughout Germany staffed by 24,500 people, mostly scientists and engineers. CW recently got a chance to tour one, Fraunhofer ICT in Pfintzal, Germany.

Read MorePlant Tour: BENTELER SGL, Ort im Innkreis, Austria

High-volume CFRP structures pioneer makes industrialization and multimaterial assembly look easy.

Read MoreCenter for mass production of lightweight composites

German R&D center brings together 8 institutes and more than 80 companies from 120 countries to help industrialize composite parts production.

WatchComposites recycling is gaining traction

Although CW’s coverage of composites recycling dates back over a decade, informal statistics still show that only ~2% of composites-related companies are active recyclers. That said, three years since our most recent feature on the subject, there is demonstrably greater interest and activity, and real applications of recycled fiber are growing.

Watch