Resins

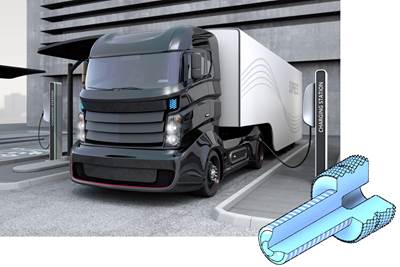

Creating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

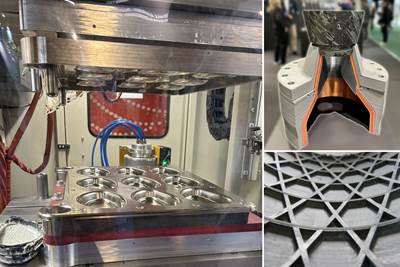

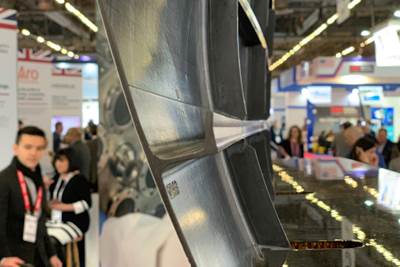

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

WatchNanopoxy, Nione jointly develop nanostructured epoxy resin

Epoxies featuring nanometric niobium pentoxide particles promote toughness, UV radiation resistance and other performance gains.

Read MoreTCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

Read MoreCRP Windform composites show high affinity for electric insulation

GFRTP materials for 3D printing were subjected to dielectric constant and dielectric strength tests, indicating strength for use in electric applications like automotive.

Read MoreSuper Resin Inc. highlights plant-based epoxy resin, foam core

Eco-friendly resin system using glycol lignin offers an eco-friendly option for CFRP structures and components, and core materials.

Read MoreHyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreLast call for ITHEC conference abstracts

The thermoplastic composites event, taking place Oct. 9-10 in Bremen, Germany, is seeking oral and poster contributions before March 31.

Read MoreFrom the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read More