Pultrusion

Scott Bader launches resins, gelcoats, adhesives for structural applications

Crestabond M7-04 is the company’s latest primer-less MMA structural adhesive.

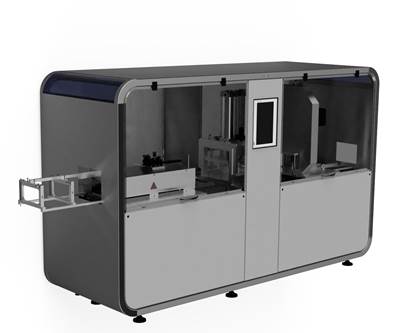

Read MoreThomas + Technik introduces modular, compact pultrusion system

At 3.5 meters long, pullCUBE is reported to be about 75% shorter than conventional pultrusion machines, and the shortest yet built.

Read MoreAcciona Construction participates in EU-funded project for accelerating nanomaterials production

Among LEE-BED project objectives, Acciona plans to embed nanomaterial-enabled wireless sensors into pultruded composite building elements.

Read MoreJEC announces finalists for 2020 Innovation Awards

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

Read MoreThe coming decade: Clarity with a strong dose of uncertainty

Columnist Dale Brosius considers the potential and uncertain role of composites in aerospace, automotive and other markets in the coming decade.

Read MoreAVK invites submissions for Innovation Award 2020 candidates

Award categories include innovative composite applications, processes or research. The application deadline is March 31.

Read MoreIACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

Read MoreFRP, pultrusion enable mobile Antarctic habitat module

Constructed of fire-retardant fiberglass-reinforced polyurethane walls and pultruded beams, the self contained living unit is designed to withstand extreme Antarctic weather conditions.

Read MoreCorebon expands induction-based composites production into new facility

Results for cutting CFRP cycle time to be presented at Carbon Fiber 2019 conference.

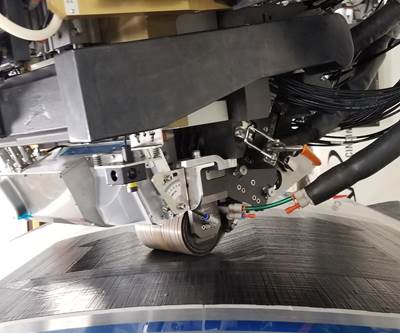

WatchScott Bader's urethane acrylate resins enable Corvette Stingray bumper beam

The company’s Crestapol resins were used for the automotive industry’s first curved, multi-hollow pultruded carbon fiber bumper beam.

Read More