Processes

VoxelMatters report reveals top companies in composites AM

The new market study identified key players in a $785 million global market that grew by 21% year on year in 2023.

Read MoreBelotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

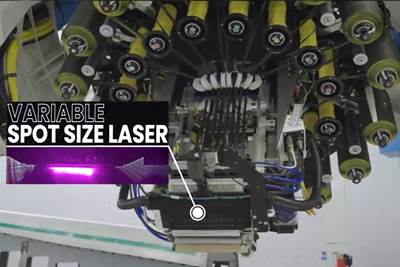

Read MoreElectroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchILAuNCH Trailblazer project to use AM technologies to produce large-scale composite rockets

ILAuNCH partnership, joined by ANU and New Frontier Technologies, will develop a qualified manufacturing process that will directly contribute to the development of launch vehicle development.

Read MoreMaterialise adds three materials to enhance industrial 3D printing

Materialise expands additive manufacturing portfolio with early adoption of new HP PA 12S and integration of PA 11 and PA-CF materials.

Read MoreFiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

Read MoreUMaine researchers aim to recycle wind turbine blades as 3D printing material

With a DOE grant in hand, UMaine’s ASCC seeks to develop an approach to recycle shredded wind turbine blade material as a cost-effective reinforcement and filler for large-scale 3D printing.

Read MoreExel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.

Read MoreCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Watch