Molds/Tools

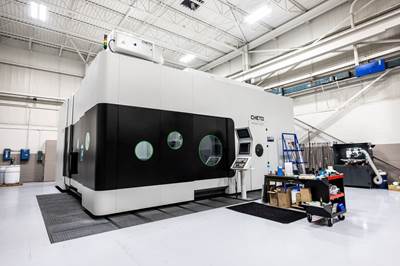

Century Tool investment boosts efficiency, capability in tooling for composites

Designer and builder of compression molds for composite structures installs seven-axis CNC deep-hole drilling and milling machine to improve productivity.

Read MoreMassivit, Sika to co-brand digital tooling materials for Massivit 10000 series

Strategic MOU initially introduces SikaBiresin CIM 120 and SikaBiresin CIM 80 to serve crucial composites market needs for 3D printing tooling, prototyping and more.

Read MoreBelotti to integrate hybrid BEAD system with Adaxis AdaOne software

Through this strategic collaboration, BEAD’s additive and subtractive capabilities for large-scale AM composite tooling production are made more accessible.

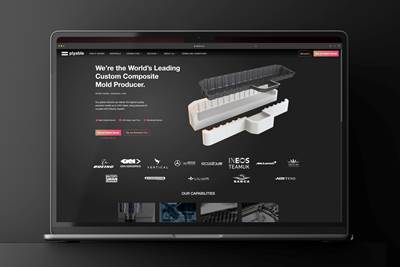

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreComprehensive group portfolio targets holistic engineering, tooling and epoxy resins

JEC World 2024: The RAMPF Group is bringing together three of its divisions — RAMPF Composite Solutions, RAMPF Tooling Solutions, and RAMPF Group Inc. — delivering a variety of materials and services to the composites industry.

Read MoreNational Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

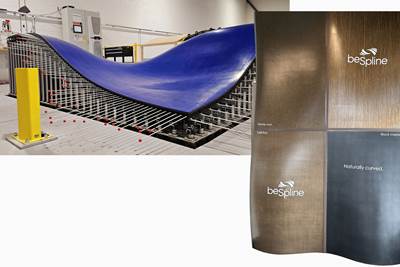

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreBelotti retrofits Vega CNC center in BEAD hybrid machine for D-Composites

Combined LSAM and five-axis CNC milling capabilities will optimize D-Composites’ production services, flexibility and cut time and cost for composite tooling manufacture.

Read MorePRF Composite Materials granted U.K. patent for Q.tool

Innovative prepreg tooling is highly drapable, capable of forming complex carbon fiber tooling shapes, in addition to reducing through thickness porosity and only requiring one debulk during layup.

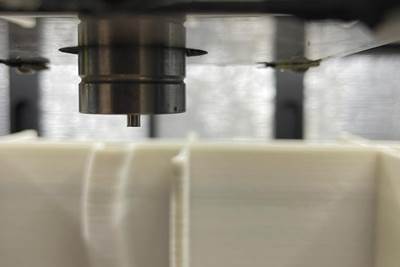

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Watch

.jpg;maxWidth=300;quality=90)