Filament Winding

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

WatchECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

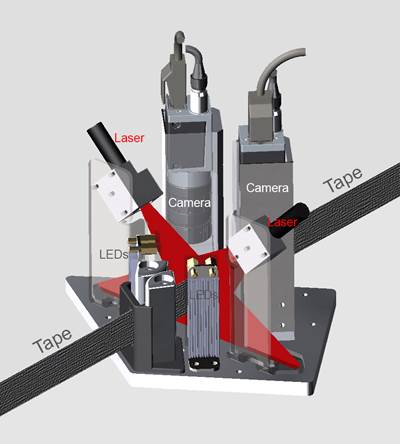

Read MoreDaQoTa project develops measuring head prototype for LATW inspection

Fraunhofer IPT, Taniq and Pixargus have proven the success of a measuring head capable of optimizing the reliability, security and efficiency of FRP pressure vessel manufacturing.

Read MoreAutomation, winding equipment meet evolving composite needs

JEC World 2024: Engineering Technology Corp. is exhibiting offerings ranging from high-speed filament winding equipment to integrated robotic solutions, in addition to new standard line of tape wrappers.

Read MoreFilament winders specialized for composites hydrogen vessel production

JEC World 2024: A pressure vessel for HydroExceed manufactured via a recently delivered multi-spindle filament winder displays Mikrosam’s expertise in filament winding equipment.

Read MoreAutomated winding machine supplier forges carbon fiber application growth

JEC World 2024: Custom-designed carbon fiber/epoxy components and automated fiber winding machine offerings will be on display, emphasizing CompoTech’s focus on designing and supplying turnkey composites technologies.

Read MoreIndustrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

WatchFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreFilament winding software focuses on efficiency, precision

JEC World 2024: Roth Composite Machinery is co-exhibiting with partner mefex GmbH to present new developments to its µRoWin software for automated filament winding.

Read More

.jpg;maxWidth=300;quality=90)