Core

Formula Electric Belgium's Titan race car features EconCore rPET honeycomb

Front wings and undertray comprise the honeycomb core material, the latter reducing wing weight by 26% compared to the previous year, and able to withstand forces 1,000 times its own weight.

Read MoreEconCore, ThermHex Waben optimize honeycomb core production

An investment in additional MEAF 75-H34 extruders reduce energy consumption in honeycomb production by up to 65% and double capacity.

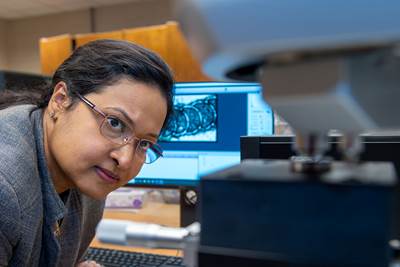

Read MoreSIU researcher to apply additive manufacturing for more efficient sandwich material production

Southern Illinois University’s Sabrina Nilufar won a two-year, $200,000 grant from the NSF to study how to make composite sandwich panels with a TPMS-based core lattice via AM.

Read MoreCorPower Ocean partners with Diab for full-scale wave energy converter

Diab provides foam core, engineering support to enable CorPower’s first commercial-scale composite filament-wound WEC.

Read MoreEvonik invests in modernized Rohacell foam production facility

The new plant, to begin production in April 2022, will ensure delivery reliability for future market demand and feature the latest technology and safety standards.

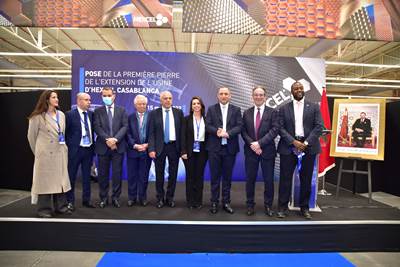

Read MoreExpansion begins at Hexcel engineered core operations plant in Morocco

The site will double in size by 2023 to meet increasing demand for lightweight advanced composites from aerospace customers.

Read MoreThermHex acknowledged as a TOP 100 innovator in Germany

Out of 436 participants, the honeycomb core specialist has been honored for its excellence in driving forward production process innovation.

Read MoreTRB Lightweight Structures contributes composite bodyshell design to passenger train demonstrator

The Revolution VLR (Very Light Rail) passenger vehicle serves to simplify existing rail networks and reopen historical lines, while adhering to rigorous rail and sustainability regulations.

Read MoreResin-infused center console boat configuration proves higher performance, speed, quality

Hayaari Marine employs a revised infusion setup using semi-permeable membranes to eliminate porosity and improve laminate consolidation, reducing about 450 kilograms of resin per boat, and offering 20% weight savings.

Read MoreCurve Works licenses 3D Core Kits to BeSpline startup

Thermoformed structural foam core kits leveraging reconfigurable mold technology are more readily available to North American manufacturers.

Read More