Compression Molding

HyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

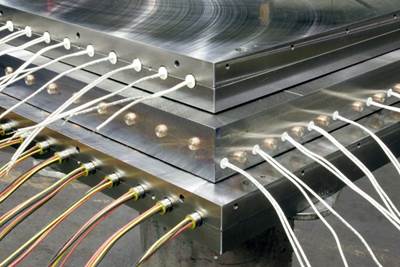

Read MoreInduction heating platen achieves dynamic temperature management

JEC World 2024: Roctool is introducing the R-IDS, a patented heated platen that aims to make mass production more accessible for composites manufacturing.

Read MoreThermoplastic tape friction tester completed at TPRC

Delivered and implemented at Toray Advanced Composites, the setup seeks to eliminate defects during hot press forming thermoplastic tapes.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreENRX, Roctool collaborate to advance mold electrification

Plastics and composites manufacturers will benefit from Roctool’s heat and cooling induction for molding processes, with increased technical service support and capability demonstrations on a global scale.

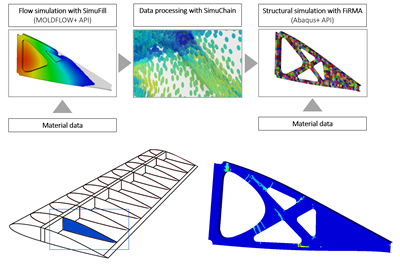

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

WatchComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreHeating platens deliver precise, uniform compression molding temperature control

CAMX 2023: Venango Machine features MultiZone heating platens with a control system included, capable of reducing mold surface temperature variation by almost 400% during the compression molding process.

Read More