Bonding/Welding

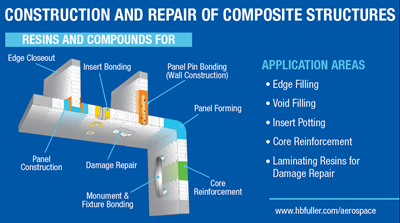

Adhesives, sealants meet aerospace and defense specifications

CAMX 2023: H.B. Fuller Aerospace manufactures, packages and delivers a variety of sealants, structural adhesives, low outgassing epoxy systems and more to industry and customer requirements.

Read MoreSupernal, Qarbon Aerospace partner to mature induction welding technologies for eVTOL scale-up

Major aerospace supplier commits resources to scale rate-enabling manufacturing processes for Supernal’s SA-A1 CFRTP component assembly.

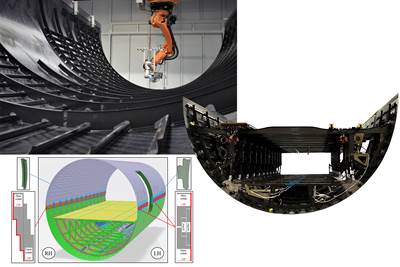

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

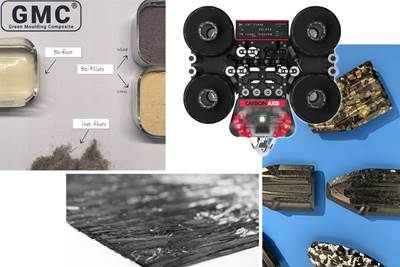

Read MoreJEC World 2023 highlights: Recycling, biocomposites, smaller equipment and expanding brands

CW senior technical editor Ginger Gardiner addresses some of this year’s hot topics, ranging from novel biocomposites and recycling technology solutions from myriad startups to upgraded, but equally sustainable, equipment from well-established companies.

WatchAerospace project secures funds for developing lightweighting technology

A joint project between ÉireComposites, Plasma Bound and TU Dublin will be supported by the DTIF.

Read MoreSpur offers Hardex structural foam core as alternative to low-weight cores in sandwich composites

Recyclable, closed-cell XPP foam offers good properties, resistance, recycled content/recyclability and thermoformability, including fusion/welding with PP-based composite skins.

WatchXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

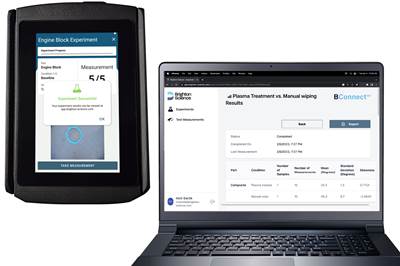

Read MoreBrighton Science unveils BConnect: The world's first surface intelligence platform

Next-generation solution combines diagnostic tools with data analytics to understand and prevent bonding and adhesion issues in composites and other industries.

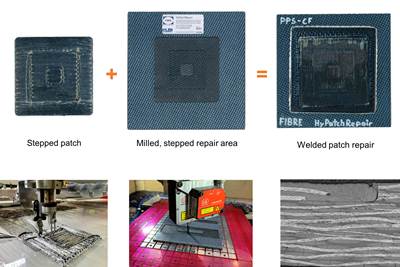

WatchDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read More