Weber Manufacturing Technologies Inc.

16566 Hwy. 12

PO Box 399

Midland, ON L4R 4L1 CA

705-526-2930

webermfg.ca

About Weber Manufacturing Technologies Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Weber Manufacturing Technologies Inc. Supplies the Following Products

- Autoclaves

- Resin transfer molding (RTM)

- Resin transfer molding (RTM)

Editorial, News, and Products

-

Plant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

CAMX 2019 exhibit preview: Weber Manufacturing Technologies Inc.

Weber will showcase a live nickel vapor deposition (NVD) out-of-autoclave demonstration for a Class A automotive body panel, demonstrating the tool’s rapid heating and cooling capabilities at CAMX 2019.

-

Weber Manufacturing expands, buys huge machine

Weber has recently installed an innovative, high-speed 5 axis machining center, a 2017 DMU 340 P Unimould by DMG Mori (Bielefeld, Germany), the first of its kind in Ontario and just the third such machine in North America.

-

Slideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

-

Weber Manufacturing Technologies: Midland, ON, Canada

With a long, storied history in composites moldmaking, this rare nickel vapor deposition specialist has built a strong niche, making large, high-quality tools.

-

Tooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

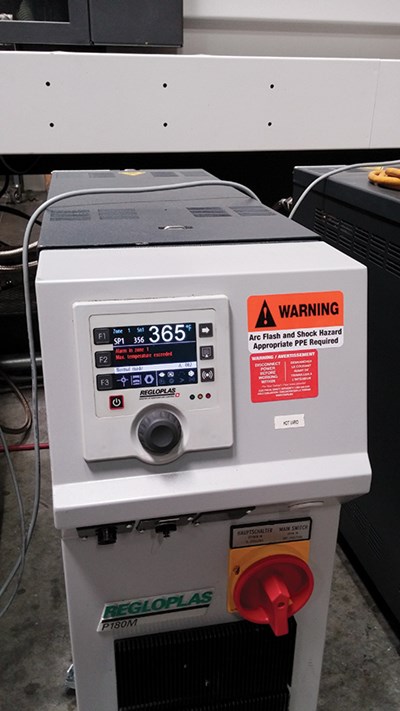

Combining curing processes for faster part production

Regloplas USA (St. Joseph, Mich.) says it has demonstrated a tool heating method that overcomes poor temperature uniformity in autoclave curing processes.

-

Revisioning the Viper: Clamshell hood challenge

Autoclave-cured carbon-fiber prepreg hood/fender combo proves as technically formidable as it is visually stunning.

-

Building a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

-

Faster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

-

In new Corvette Stingray, another step forward for composites

Plasan Carbon Composites puts its "pressure press" process, developed with Globe Machine, to work in the manufacture of the hood and roof for the new 2014 Corvette Stingray, introduced last week at the Detroit Auto Show.

-

Auto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

-

Tooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

JEC Composites Show 2010 Highlights

Despite the volcanic ash that clouded air travel, an eruption of new technology and new business did much to dispel the clouds of economic recession.

-

Gurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

-

SAMPE 2009 Product Showcase

Showgoers at the SAMPE 2009 Conference and Exhibiton in Baltimore, Md. found many suppliers undeterred by poor economic news.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

SAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.

-

Tooling Update: New dimensions in tooling

Nanoenhancements, out-of-autoclave strategies and low-pressure RTM headline efforts to increase mold quality and productivity and cut tool cost.

-

Inside Manufacturing: Tooling Method Replicates Intricate Woodgrain in Fiberglass Doors

Toolmaker becomes molder to offer the beauty of natural wood and the durability and weatherability of composites to residential entry door OEMs.