Voith Composites SE & Co. KG

Voith Group

Daimlerstr. 27

Garching bei München, 85748 DE

49 89 32001 800

voith-composites.com

About Voith Composites SE & Co. KG

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Voith Composites SE & Co. KG Supplies the Following Products

- Abrasive tools

- Adhesive applicators

- Adhesive bonding

- Aerospace, aircraft interior

- Aramid

- Automated fiber placement

- Automated fiber placement systems

- Automotive, body panels & substructures

- Bonding equipment

- C-Glass

- CAD/CAM/CAE design

- CAD/CAM/CAE hardware/software

- Carbon, PAN-based

- Carbon/carbon composites

- Civil engineering

- CNC machining equipment (multiaxis)

- Coaters

- Coating and painting

- Compressors

- Computer controls and software

- Consulting, business development/acquisition

- Consulting, materials

- Consulting, process development

- Consulting, structural design

- Continuous laminating

- Creels and bobbins, for fiber

- Curing ovens/lamp arrays

- Cutting equipment, knife

- Cutting equipment, manual

- Cutting equipment, ultrasonic

- Diaphragm forming

- Drilling and cutting tools

- Drying equipment

- E-Glass

- Environmental testing equipment

- Epoxy, 250 F cure

- Epoxy, 350 F cure

- Epoxy, toughened

- Eye protection

- Fatigue-testing equipment

- Fiber-handling equipment for SMC, pultrusion, filament winding

- Filament winding

- Filament winding machines and controls

- Films, masking

- Finite element modeling/analysis (FEM/FEA)

- Fire-retardant

- Gasket materials for vacuum bags

- Gloves

- Hand cleaners

- Hand layup

- Hardness testers

- Heat tapes

- Heaters

- Impregnation lines

- Injection molding

- Inserts

- Laminate sheets, solid

- Laminate thickness gauges

- Mandrels, steel

- Marine, other

- Market research

- Materials analysis

- Metal bonding

- Metal, aluminum

- Metal, steel

- Modeling/simulation/virtual testing software

- Nesting software

- Other composite structures

- Other fabricating services

- Other tools/tooling supplies

- Ovens

- Potable-water grades

- Presses, compression molding

- Presses, diaphragm forming

- Presses, hydraulic

- Presses, injection Molding

- Presses, low-pressure

- Presses, vacuum

- Pressure forming

- Printing/marking equipment

- Process controls

- Product design

- Profiles

- Prototype

- Prototyping

- Repair ovens

- Resin content analyzers

- Resin injection

- Resin transfer molding (RTM)

- Resin transfer molding equipment (RTM)

- Rotational molding

- RTM/resin infusion

- Sealing tapes and materials

- Shim materials

- Surface treatment

- Tape laying

- Temperature control devices

- Tensioning equipment

- Thickness measuring equipment

- Trimming equipment

- Tubes

- Vacuum bagging materials, polymide

- Vacuum bagging materials, silicone

- Vacuum valves and pumps

- Vacuum/repair tables (heated/unheated)

- Viscosity measurement equipment

Editorial, News, and Products

-

Composites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

-

Composites, resins portfolio supports EV applications, sustainability

JEC World 2024: Huntsman is sharing a new polyurethane- and epoxy-based composites portfolio aligned with the needs of the automotive sector.

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

Air New Zealand uses Beta’s Alia for Mission Next Gen Aircraft program

The composites-intensive electric aircraft was purchased to meet the airline’s goal of flying a commercial demonstrator by 2026.

-

Voith Composites certifies towpreg-wound Carbon4Tank for on-road use

Type IV hydrogen storage tank has earned type approval under UNECE R 134 after meeting stringent performance requirements.

-

VIDEO: Sustainable pressure vessel systems for heavy-duty vehicles

Automotive and filament winding experts at Voith Composites showcased their Type IV hydrogen storage tanks at JEC 2023. These 350-liter pressure vessels, manufactured with recycled carbon fiber, are primarily designed for heavy-duty vehicles.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

Voith H2 storage tanks made with in-house towpreg winding

Plug & Drive H2 storage system displayed at IAA Transportation 2022 uses 700-bar tanks for heavy-duty commercial and construction vehicles.

-

HORYZN emergency UAV harnesses CFRP tooling from Voith Composites

Voith Composites collaborated with HORYZN, a student initiative that leverages CFRP tooling and composites know-how for its Mission Pulse UAV project.

-

Voith Composites partnership with Gazechim Group delivers Carbon4Tool tooling system to Europe

With Gazechim Group as the European distributor, Voith hopes to empower faster, easier and more effective CFRP tool manufacturing via its next-generation technology.

-

JEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

-

Voith Composites, V-Carbon to develop closed-loop solution for CFRP used in hydrogen tanks

The Voith Composites and V-Carbon partnership will accelerate growth in sustainability by enabling the reuse and a second life for carbon fiber in the pressure vessels market.

-

JEC World reveals 2022 Innovation Awards finalists

Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry, with 30 finalists in ten categories.

-

Voith updates roving applicator generation technology

Voith GmbH is featuring carbon fiber-reinforced polymer (CFRP) components such as tailored stacks for the automotive and aerospace sectors.

-

Voith Composites, HRC to develop hydrogen pressure vessels for EVs

The next-generation filament-wound composite high pressure vessels will be designed for use with fuel cell electric vehicles.

-

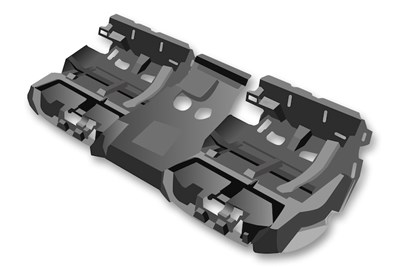

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

Reflections on carbon fiber

Highlights from the December 2018 Carbon Fiber conference include industry leader predictions about commoditization of composites, next-generation aircraft and automotive.

-

AVK presents its 2018 Innovation Awards

The 2018 AVK Innovation Awards were presented at the International Composites Congress (ICC) on Nov 5, chosen from more than 50 submissions.

-

Voith wins Lightweight Design Award

Voith’s VRA technology for CFRP production lines is said to reduce waste and thus material costs by depositing carbon fibers close to the final shape.

-

Rear wall reboot: One-stop, tow to tape to CFRP part

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

-

Voith unveils digital carbon fiber manufacturing line

Patented production line used to produce the carbon fiber reinforced plastic rear panel for the new Audi A8.

-

Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

-

Fraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

-

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

-

JEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.