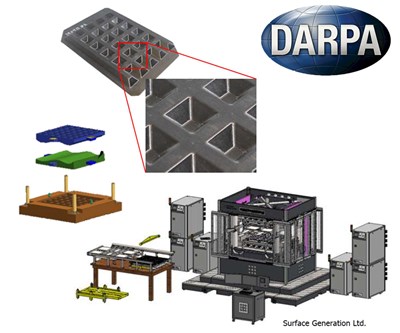

Surface Generation Ltd.

Brackenbury Ct., Lyndon Barns

Edith Weston Rd., Lyndon

Oakham, Rutland, LE15 8TW GB

44 1572 737011

surface-generation.com

About Surface Generation Ltd.

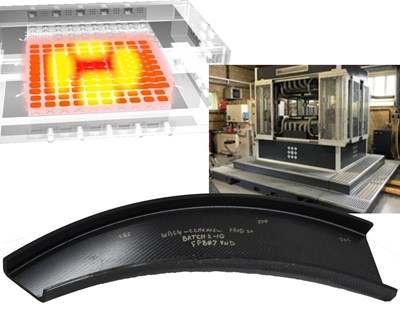

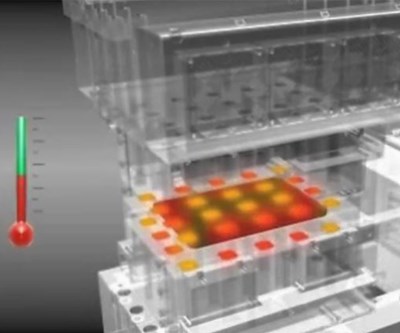

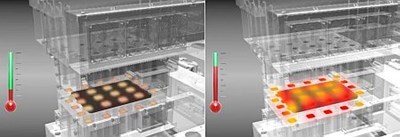

Integrated production solutions for in-autoclave and out-of-autoclave processing. Turnkey and retrofittable mold tool, heating/cooling, sensing and control provide step changes in ramp rates (to 200°C/min), thermal performance (to 750°C), control (+/-0.5°C), quality control and energy consumption (<90%).