Oak Ridge National Laboratory

1 Bethel Valley Rd.

PO Box 2008, MS-6196

Oak Ridge, TN 37831 US

865-5743980

web.ornl.gov/manufacturing

About Oak Ridge National Laboratory

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Oak Ridge National Laboratory Supplies the Following Products

- Materials analysis

- Product design

- Testing, materials

- Testing, product

Editorial, News, and Products

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

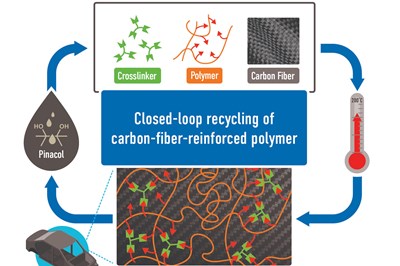

ORNL develops dynamically crosslinked CFRP, enabling closed-loop recycling

At laboratory scale, functionalized CFRP thermosets can be “released” via heat or chemicals to reincarnate them back into their starting materials.

-

Scaling up sustainable solutions for fiber-reinforced composites

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Composite current collectors to enable EV battery efficiency

Researchers at ORNL have developed a metal-free current collector using carbon fiber and nanotubes to further lightweight lithium-ion batteries and increase energy density, improving EV driving range.

-

Composites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

-

ORNL conducts sustainability analysis of 3D-printed composite molds

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

-

ORNL, Zeiss to improve CT inspection for 3D-printed parts

Five-year research collaboration starts with metal AM parts and is considering 3D-printed composites next, incorporating machine learning into CT scanning to reduce time, cost of inspections by 10 times and improve quality.

-

Optima 3D demonstrates new 3D weaving technology for ASCC

U.K. company will install compact system with innovative shuttle and digital twin capability for soft and hard composite structures at University of Maine’s new textile lab.

-

People in composites: June 2023

This month’s roundup includes new personnel announcements made by Archer Aviation, ORNL and Bye Aerospace.

-

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

-

Orbital Composites licenses AMCM technology

Additive manufacturing compression molding (AMCM), co-developed with ORNL, combines robotic AM and continuous fiber technologies to revolutionize high-volume composites manufacturing.

-

People in composites: April 2023

Concordia Engineered Fibers, Nawa Technologies, IACMI, Joby Aviation and Akarmak America have made new personnel announcements in April 2023.

-

IACMI receives funding renewal from U.S. DOE to continue composites R&D

Over the next five years, IACMI aims to further composites R&D efforts to support U.S. decarbonization and its pillars: technology, economy and workforce development.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

University of Maine unveils 100% bio-based 3D-printed home

BioHome3D, made of wood fibers and bioresins and entirely 3D printed, highlights Maine’s effort to address the need for more affordable housing.

-

ORNL develops recyclable polymer for low-carbon composites manufacture

Novel vitrimer polymer prevails over the intrinsic limitations of conventional epoxy vitrimers, driving net-zero goals forward.

-

IACMI names Chad Duty as CEO

Duty will fully assume his new role as CEO in April 2023, while continuing his position as an engineering professor at the University of Tennessee, Knoxville.

-

Full conference programming announced for CAMX 2022

The conference program’s list of eight featured sessions have been released for this year’s event in Anaheim, California, focusing on the composites industry’s hottest topics.

-

Carbon Fiber 2022 finalizes conference agenda

Companies like GKN Aerospace, Lilium, Forward Engineering, LM Wind Power and others will present at the composites industry’s preeminent carbon fiber event, Nov. 15-17, 2022 in Greenville, S.C.

-

Low-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

-

Fortify, polySpectra awarded $3 million by DOE to advance 3D-printed tooling

Fortify is to develop inexpensive, durable solutions for lightweighting automotive components using polymers, composites and metals, advancing vehicle part commercialization.

-

Moving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

-

IACMI, N.C. A&T State University to lead DOD regional machine tool workforce training center

America’s Cutting Edge (ACE) hub aims to revitalize and close the skills gap for the U.S. machine tool industry, and from there, advanced manufacturing capabilities.

-

Can 3D printing debottleneck prototype tool production?

Preliminary IACMI/ORNL study evaluates viability of using polymer additive tooling to compression mold SMC.

-

Volkswagon launches new research collaboration with ORNL, University of Tennesse, Knoxville

Projects involve integration of advanced functional materials, novel recycling and wireless charging concepts to support electric mobility and sustainable transportation.

-

NREL explores novel manufacturing approach for next-generation wind turbine blades

3D printing of thermoplastic blades enables thermal welding and improves recyclability, offering the potential to reduce turbine blade weight and cost by at least 10%, and production cycle time by 15%.

-

MVP releases new model of RAM system for thermoset materials

New large-format AM machine model, RAM 48, maximizes production efficiency and enables custom build dimensions when fabricating thermoset materials.

-

CAMX 2021 Show Daily highlights composite technology innovations

As the CAMX media sponsor, CompositesWorld reported on several new or improved developments on display, from CAMX Award and ACE Award winners, to the keynote speaker and interesting technologies.

-

SAMPE names 2021 Young Professional of the Year, North American Award winners

Young Professional of the Year award recognizes the achievements of those who have graduated from university and are under the age of 35. North American Award winners reflect those who have succeeded in delivering on SAMPE’s mission.

-

Composites AM research targets wind energy

The U.S. DOE, universities and industry leaders ramp up new efforts and funding to develop 3D-printed composite wind blade molds and end-use blade components.

-

MVP large-format system prints thermoset resins

Magnum Venus Products’ Reactive Additive Manufacturing (RAM) system is a large-format AM machine that prints with fiber-reinforced thermoset resins.

-

Additive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

-

Orbital continues to progress toward commercialization

Orbital Composites is pursuing a variety of collaborative projects to apply its Orbital S robotic additive manufacturing system.

-

Cincinnati’s BAAM proves utility of recycled materials in AM

Cincinnati Inc. modified the extruder of its Big Area Additive Manufacturing (BAAM) system to be able to process virgin carbon fiber/ABS and recycled carbon fiber/ABS.

-

Cincinnati Inc. BAAM printer demonstrates 3D printing with recycled composites

Dual-material thermoplastic extrusion system produces monolithic composites tool exceeding 10 feet in length, without manual intervention.

-

Orbital Composites to demonstrate containerized 3D printing robots for AM wind blade manufacture

Project aims to demonstrate additive manufacturing of >100-meter-long composite wind blades with >25% reduced cost.

-

Thermoplastic tapes reinforced with textile-based PAN carbon fiber

IACMI project trials inline production of thermoplastic tapes reinforced with textile-based PAN carbon fiber.

-

GE to research AM for wind turbine blades

Twenty-five-month project to couple low-cost thermoplastic skin with AM for high-performance wind blade designs to be used on large rotors.

-

UMaine awarded $2.8 million to accelerate AM wind blade development

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

-

ORNL develops 3D-printed composite machine base

In a recently reported project from Oak Ridge National Laboratory, carbon fiber and large-format 3D printing were used to help create a solution for machine tool outsourcing.

-

Orbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

-

University of Kentucky, ORNL partner to turn coal into high-value carbon fiber

The $10 million research partnership will focus on creating energy-efficient and cost-effective processes for the manufacturing of carbon fiber.

-

IACMI collaboration aims to develop carbon fiber for hydrogen storage tanks

The $2.7 million U.S. Department of Energy funding supports the vision for affordable hydrogen production, storage distribution and use.

-

Techmer PM, SK Capital strategic partnership better serves global customers

The investment enables Techmer to satisfy growing demands from brand owners and international clients.

-

DOE announces funding for projects supporting composites for vehicle applications

Composite recipients Ford and GM will develop a multi-functional cross-car beam and volume manufacturing of structural battery enclosures.

-

Composites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

-

Commercial-scale carbon fiber recycling comes to Tennessee

Accepting carbon fiber waste materials now, Carbon Fiber Recycling will recycle 2,000 tons of carbon fiber waste per year at its Tennessee facility.

-

Developing new solutions to multimaterial joining

Several recent IACMI partner projects focus on technology innovation related to challenges in multimaterial joining for the wind and automotive sectors.

-

Enabling a circular economy approach to advanced composites innovation, manufacturing and use, Part 2

IACMI chief technology officer Uday Vaidya reflects on IACMI’s role in improving composites’ recyclability and reusability.

-

Volkswagen, ORNL, UT collaborate on innovation hub

Initial work at Volkswagen’s first North American innovation hub will focus on developing composite vehicle components and electrification of vehicles.

-

ORNL, AddUp collaborate on additive manufacturing for tooling applications

As part of an R&D agreement, AddUp and the Oak Ridge National Laboratory are developing industrial laser powder bed fusion technology for complex tooling.

-

IACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

-

University of Tennessee adds advanced manufacturing certificate

Available in-person or online, the advanced manufacturing program will begin offering classes in January 2020.

-

Carbon fiber/epoxy for automotive mass reduction, mass production

IACMI precompetitive research explores carbon fiber-reinforced prepreg, SMC with novel matrix for structural passenger-car applications.

-

UMaine Composites Center's 3D printer named world's largest

The university now holds world records for the largest prototype polymer 3D printer, largest solid 3D-printed object and largest 3D-printed boat.

-

CAMX 2019 technical paper, poster session award winners announced

The award winners include researchers from Oak Ridge National Laboratory, National Research Council Canada, Mitsubishi Electric and several U.S. university programs.

-

Additive manufacturing reimagined: large-scale, fiber-reinforced thermoset printing

ORNL, MVP and Polynt-Reichhold launch world’s first commercially available, large-scale thermoset composite additive manufacturing machine and reactive print material.

-

New research collaboration to advance efforts to 3D print with wood products

The ORNL and UMaine research team will work with the forest products industry to produce new bio-based materials that will be conducive to 3D printing a variety of products.

-

Research of developing coal, oil into low-cost carbon fiber advances

Western Research Institute and academic and industry partners advance into the second year of a research project to turn coal, crude oil and biomass into low-cost carbon fiber.

-

Harper, Oak Ridge National Labs progress in carbon fiber simulation joint project

The companies have completed the first phase of the joint project, developing a computational model for low-temperature pre-carbonization furnaces.

-

ORNL develops lignin-based composite 3D printing material

Researchers have found that combining lignin with nylon yields a composite with increased room temperature stiffness and decreased melt viscosity.

-

CAMX 2018: Big changes coming

3D printing goes thermoset, pultrusion aims at automotive, a polyester resin with Tg>250°C and much more from the Dallas exhibit floor.

-

Musings on my first CAMX

Insights and inspiration from the 2018 Composites and Advanced Materials Expo which was held in Dallas, TX, US last week.

-

IACMI consortium aims to close the loop on automotive carbon fiber prepreg scrap

Carbon fiber recycling start up Vartega leads a project to close the loop on automotive carbon fiber prepreg manufacturing scrap for use in new automotive applications.

-

2018 CAMX Award finalists announced

The winning entries will be announced and presented during the General Session at CAMX on Tuesday, Oct.16 in Dallas, TX, US.

-

Ingersoll showcases 3D printed winglet layup tool at IMTS

The part was printed with large 3D printing technology developed by Ingersoll Machine Tools and Oak Ridge National Laboratory.

-

IACMI and ORNL showcase additive manufacturing advancements at IMTS

Demonstration followed the journey of an additively manufactured metal die as it was 3D printed, machined and used to mold advanced composite parts.

-

IACMI announces collaborative smart composite pressure vessel project

The goal of the collaboration is to develop structurally predictable, low-cost smart composite pressure vessels (SCPVs) with integrated health-monitoring.

-

Additive manufacturing: Big and going commercial

A demonstration of large-format 3D printing delivers parts for an excavator cab, from CAD data to ready for assembly, in only five hours.

-

4M, ORNL and RMX Technologies to manufacture low-cost carbon fiber from textile PAN

The project’s objective is to demonstrate that standard modulus carbon fiber can be made from textile grade PAN precursor using less energy and processing time.

-

The spread of spread tow

Advancing from “lighter and thinner” to boosting strength, stiffness, impact resistance and productivity, spread tow unlocks new applications and markets.

-

MVP and ORNL install first commercially available medium/large-scale thermoset 3D printer

MVP engaged with ORNL to create a 3D printer capable of printing large-scale thermosets, chemistries that are irreversibly cured from a prepolymer or resin.

-

ORNL offering additive manufacturing/composites post-doc

The postdoctoral position at Oak Ridge National Laboratory (ORNL) will conduct research in additive manufacturing related to advancement of current technologies, implementation of new processes, and development of material systems.

-

CAMX 2017: Highlights from the floor

3D printing and nanotechnology developments promise to cut time and cost in composite structures production while recycling and sustainability continue to grow in importance.

-

Carbon Fiber 2017 final highlights

Applications and enabling technologies for carbon fiber promise new market penetration – challenges notwithstanding.

-

Composites and Industry 4.0: Where are we?

As the tide of the Fourth Industrial Revolution rolls in, how will composite manufacturers ride the wave?

-

CAMX 2017 preview: Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) is showcasing several next-generation manufacturing technologies from the US Department of Energy’s Manufacturing Demonstration Facility at ORNL.

-

Preforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

-

Earth Stewardship: The future of composites development

Investing in Manufacturing Communities Partnerships holds great promise for advanced composites.

-

CAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

-

Cincinnati Inc., ORNL sign additive manufacturing patent agreement

Under the agreement, Cincinnati Inc. may make, use or sell the lab’s patented developments of enhanced additive manufacturing.

-

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

IACMI – One insider’s perspective

A CW columnist, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (Knoxville, TN, US), Dale Brosius asks, “What if we took a ‘big hat’ approach to reach faster, more cost-effective solutions?”

-

Alternative precursor R&D: First commercial use of lignin carbon fiber?

GrafTech International (Independence, OH, US) is working with Oak Ridge National Laboratory (Oak Ridge, TN, US) and the US Department of Energy’s Advanced Manufacturing Office to develop lignin fiber manufacturing and demonstrate it in viable products.

-

Alternative precursor R&D: Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) has been at the forefront of North American research into alternatives to the polyacrylonitrile (PAN) precursor used to make aerospace-grade carbon fiber.

-

Alternative precursor R&D: Lignin in the lightweighting limelight

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

SPE’S ACCE 2015 Preview

Automotive composites remain a hot topic in the Motor City.

-

3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

-

Additive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

-

Can IACMI propel us out of adolescence, into adulthood?

On Jan. 9, the US Department of Energy (DoE) announced that it will add US$70 million to the US$189 million already committed to the University of Tennessee’s Institute for Advanced Composites Manufacturing Innovation (IACMI) for composites R&D. CW's editor-in-chief Jeff Sloan asks, "What will come of this investment?"

-

JEC Americas 2014 Review

Composites industry exhibitors at this combined show emphasized the textile side of the fiber/resin mix and touted process automation.

-

Faster is better, but collaborative manufacturing is essential

Guest columnist Dale Brosius, president of Dayton, Ohio-based Quickstep Composites, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), points out two key trends evident at JEC Europe 2014.

-

HPC goes to SPE ACCE

CT Editor-in-chief Jeff Sloan fields initial reports from two CT staffers about the recent — and growing — Society of Plastics Engineers' Automotive Composites Conference and Exhibition.

-

SPE's ACCE 2013 preview

Growth in 2012 necessitates a new venue and an expanded program.

-

Will carbon fiber be ready to join the 54.5-mpg battle?

Guest columnists Lindsay Brooke, senior editor of the Society of Automotive Engineers’ (SAE) Automotive Engineering International magazine, says Carbon fiber’s decades-long promise in automotive composites might, indeed, be realized.

-

Market Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

-

Optimizing materials selection in automotive and aerospace structures

Advanced materials analyst Ross Kozarsky (Lux Research, Boston, Mass.) looks at composites and competing metals in the multimaterial car of the future.

-

SPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

-

SAMPE 2012 Report

The Society’s return to Baltimore is a boost to the advanced materials community and an occasion for interesting industry buzz.

-

Carbon fiber market: Gathering momentum

All signs point to increasing demand from many market sectors. Will capacity keep pace?

-

CF 2011: Comment on end-markets and initiatives

Six speakers at the Carbon Fiber 2011 conference (December 2011) report on their organizations' activities in the carbon fiber market.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

2011 High-Performance Resins Highlights

Attendees reviewed the current state of advanced resin technology and the tests that lay ahead for expanding composites into new applications and markets.

-

Taking the long view in recovery

Composites Technology magazine's managing editor Mike Musselman points out that there is one positive phenomenon that grew up in the recent economic bubble and has, thus far, to the eventual benefit of all, survived the bust. It’s called open innovation.

-

Carbon fiber market: Cautious optimism

As the recession recedes, the demand for carbon fiber, and the supply to meet it, will exceed prerecession expectations.

-

SPE ACCE 2009 Show Highlights

The Society’s annual conclave highlights composites use in new hybrids and electrics and its prospects in a “post-depression” auto industry.

-

Researchers nano-enhance natural fiber

Mississippi State University uses nanoparticle impregnation to improve the performance of kenaf fiber in composites.