Design Concepts / Marine Concepts

JRL Ventures LLC

2443 SW Pine Island Rd.

Cape Coral, FL 33991 US

239-283-0800

dcmc-us.com

About Design Concepts / Marine Concepts

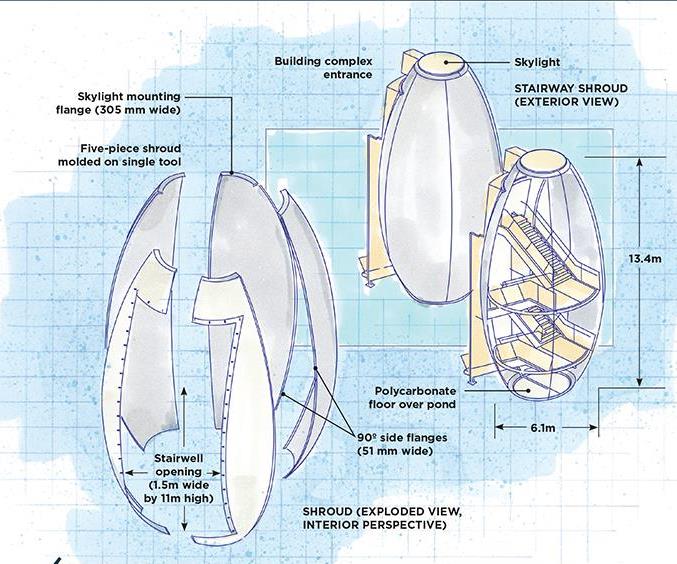

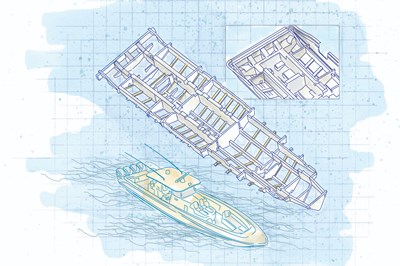

We are a cutting edge composites manufacturer that has been in business for over 40 years, DCMC manufactures CNC plugs, composite molds, CNC molds, CNC parts, composite parts - even limited production, scale models, and CNC cold mold kits.