DuPont

1250 Harmon Rd.

Auburn Hills, MI 48326 US

248-391-6300

dupont.com/mobility

About DuPont

A leading provider of composites, polyurethanes, elastomers, films, fluids, adhesives, emissions solutions and acoustic-management materials to the global transportation industry. Works collaboratively with passenger vehicle, commercial transportation and aftermarket customers to develop industry-leading solutions.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

DuPont Supplies the Following Products

- Automotive, body panels & substructures

- Carbon/carbon composites

- Consulting, materials

- Consulting, process development

- Epoxy, Other

- Epoxy, Solvent-based

- Epoxy, Water-based

- Product design

- Urethane, Other

- Urethane, Water-based

Trade Names Offered by DuPont

Editorial, News, and Products

-

Adhesives, material solutions promote end market versatility

CAMX 2023: Rudolph Bros. and Co. highlights its role as a prominent specialty chemical distributor and solutions provider with a display of high-performance adhesives, sealants, materials and more from well-known manufacturers.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

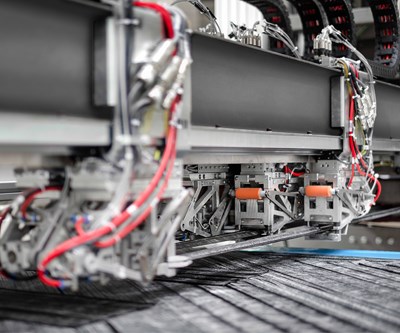

Rear wall reboot: One-stop, tow to tape to CFRP part

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

-

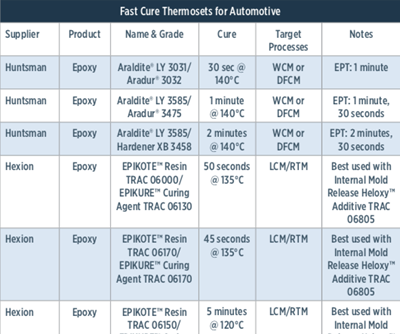

Fast and Faster: Rapid-cure resins drive down cycle times

New systems include sub-1-minute cures ideal for higher automotive production volumes.

-

Voith unveils digital carbon fiber manufacturing line

Patented production line used to produce the carbon fiber reinforced plastic rear panel for the new Audi A8.

-

Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

-

Aston Martin and Dow announce continuation of technical partnership

Partnership paves the way for further joint advancement to drive innovation and engineering excellence.

-

iComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

-

Highlights: SPE ACCE 2017

The Society of Plastics Engineers Automotive Composites Conference and Exhibiton (SPE ACCE), held Sept. 6-8 in Novi, MI, US, remains the composites industry’s go-to event for the latest on technology and equipment for automotive composites design, tooling and fabrication.

-

JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

-

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

-

Metal + composite = Less weight, more room

Global supplier develops scaled design approach for metal/composite hybrids in highly loaded automotive applications.

-

Breathing-mold process yields sandwich composite from LFT

In-cavity foaming and controlled mold-opening technique creates core and faceskins from a single injection molded material, reducing part mass and boosting performance.

-

Structural adhesives, Part I: Industrial

Today’s myriad chemistry options enable formulators to tailor adhesives to customers' exact application requirements.

-

Form + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

-

JEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

-

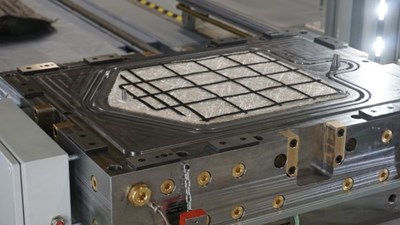

Wet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

-

VOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

-

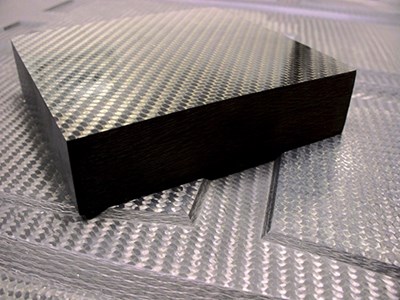

Automotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

SPE ACCE report

Automotive composites still on the horizon — are they getting closer?

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

Dow epoxy joins the fast-cure race

Dow Automotive made waves at JEC Europe with the debut of VORAFORCE 5300, a low-viscosity, <90-second cure epoxy for automotive composites molding applications.

-

Automotive, going forward?

CT editor-in-chief Jeff Sloan asks when, if and how composites professionals will be ready to meet the challenges of significant use of carbon fiber composites in automobiles.

-

Carbon fiber composites: Into the automotive mainstream?

Altair Engineering Inc.'s (Troy, Mich.) VP of aerospace solutions Robert Yancey asks if automakers will follow aeromanufacturers in embracing carbon fiber.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Optimizing materials selection in automotive and aerospace structures

Advanced materials analyst Ross Kozarsky (Lux Research, Boston, Mass.) looks at composites and competing metals in the multimaterial car of the future.

-

SPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

-

Auto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

-

SAMPE 2012 Report

The Society’s return to Baltimore is a boost to the advanced materials community and an occasion for interesting industry buzz.

-

Composites reshaping auto industry

HPC editor-in-chief Jeff Sloan observes signs at the JEC Europe 2012 trade show that indicate the auto industry is seeking to partner with suppliers int he composites industry on lightweighting strategies for prpduction passenger vehicles.

-

Automotive composites: Structural underbody

For Detroit’s Big Three, a joint precompetitive composite design, development, fabrication and testing program nears successful completion.

-

What's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

-

Engineering Insights: Glass/Thermoplastic Hood Steps Toward Commercialization

The hood design for Hyundai’s QarmaQ concept car is evaluated against European and Japanese pedestrian safety requirements.

-

Reinforced Thermoplastics: LFRT/GMT Roundup

Recent advancements in these reinforced thermoplastic technologies are expanding their performance, enabling new applications.

-

Reinforced Thermoplastics: LFRT vs. GMT

As the suppliers of long fiber-reinforced thermoplastics and glass-mat thermoplastics battle for market supremacy, the winner is … the composites OEM.