Cevotec GmbH

Biberger Str. 93

Unterhaching, 82008 DE

49 89 2314 165 0

cevotec.com

About Cevotec GmbH

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Cevotec GmbH Supplies the Following Products

- Automated fiber placement

- Automated fiber placement systems

- CAD/CAM/CAE design

- Consulting, other

- Consulting, process development

- Consulting, structural design

- Education/Training

- Other composite structures

- Other primary manufacturing equipment

- Preform manufacturing equipment

- Prototyping

Editorial, News, and Products

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

-

AZL collaborative project to redefine hydrogen tank development

Kick-off meeting sparks comprehensive discussions on materials, manufacturing and design, setting the stage for composite-based hydrogen vessel solutions.

-

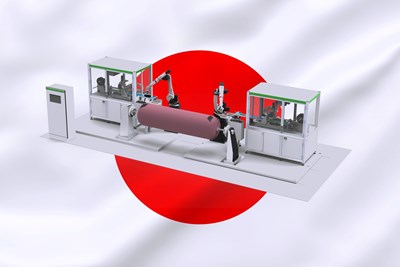

Fuji Industries purchase brings FPP-based Samba Pro PV to Japan

Dedicated to the production of hydrogen pressure vessel reinforcements, Cevotec’s specialized FPP system will be made accessible to Japanese industry through Fuji, including aerospace and composites research.

-

Cevotec Samba Pro installed in Fraunhofer IGCV AI research hall

Prepreg system is available to companies interested in exploring research in digitalization and AI for composites manufacture or to evaluate FPP-designed components.

-

People in composites: August 2023

New hires and promotions have been announced this month by composites-related companies Cevotec, Tri-Mack, Norplex, ABC Polymer Industries, Belzona and Gefran Inc.

-

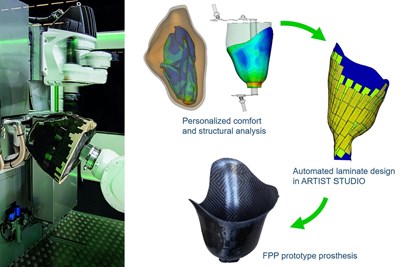

Cevotec’s fiber patch placement is part of digital process chain for automated composite prosthetics

Multiple partners work to develop automated data collection, composite laminate generation for customized medical applications using FPP technology in German-funded Patch2Patient project.

-

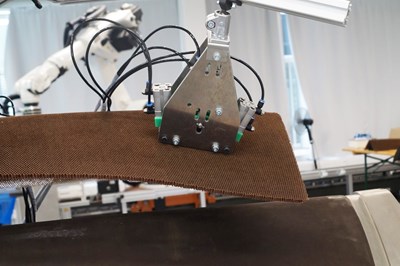

ACoSaLUS project updates for automated sandwich panel layup

Cevotec and project partners have made significant progress in line with 2023 completion, including improvement of automated handling, patch vision inspection, and the laminate design and patch placement process.

-

Cevotec welcomes Multistation as commercial FPP partner in France

Together, both companies will provide solutions that support French manufacturers and further optimize their composites production efficiency.

-

Cevotec grows commercial activities in China

Collaboration with two new international sales partners will bring Cevotec’s fiber patch placement (FPP) technology to the forefront of the Chinese composites industry.

-

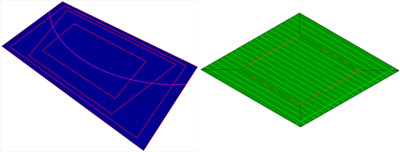

Artist Studio algorithm enables near-parallel curve creation on CAD surfaces

Cevotec introduces a novel parallel offset algorithm to its CAD-CAM software for the generation of equidistant curves from a master curve on arbitrary surfaces.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

CAMX 2022 exhibit preview: Composite Automation

Composite Automation is joined by Isojet Equipements and PCM/Lucas Industries, bringing solutions for every step of the composites manufacturing process to one booth.

-

CAMX 2022 exhibit preview: Cevotec

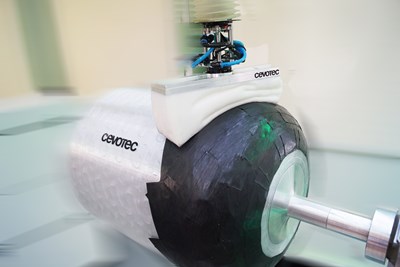

The company’s carbon fiber pressure vessel dome reinforcement using FPP technology effectively cuts cycle time and material consumption while increasing storage efficiency by 19%.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Cevotec integrates trapezoid-shaped patches into FPP Artist Studio software

Patch Artist module facilitates more even distribution of patches along tight curves during pressure vessel dome reinforcement, resulting in an optimized laminate thickness.

-

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

-

Cevotec commissions advanced SAMBA Pro Prepreg system with six-axis robots to Leonardo

A system first with two six-axis robots for tool manipulation and patch placement, increasing the capabilities to process larger, more complex part geometries for composite aerostructure applications.

-

Cevotec seeks to expand team to support growth in H2 composite tank production

The dynamic, Germany-based company is looking for analytical, results-driven individuals to fill five vacant positions on its technical and software development teams.

-

WSU-NIAR successfully commissions Cevotec’s SAMBA Pro Prepreg system

Installation at NIAR’s ATLAS facility will drive new R&D opportunities for U.S. customers and interested parties, further establish fiber patch placement for composites manufacturing on an international level.

-

Hydrogen is poised to fuel composites growth, Part 2

Potential for Type IV composite tanks in H2 refueling stations and distribution, plus targeted cost reductions and emerging technologies for tank recertification and monitoring.

-

Cevotec's MAI ACoSaLUS project aims for full automation of composite sandwich structure production

Cevotec works with GKN, TU Munich, SGL Carbon and Augsburg University with an aim to fully automate layup of sandwich parts using FPP, achieve 7-10 times improvement in layup speed.

-

CAMX 2021 exhibit preview: Cevotec

Cevotec conceptualizes the Samba PV, an automated fiber layup system that combines filament winding with automated fiber patch placement for optimized composite pressure vessel production.

-

Samba Step system expands composites research for Augsburg University

Germany-based university intends to use Cevotec’s FPP-based Samba Step system for field research of ceramic fiber composites.

-

CW Tech Days webinar explores composites in the hydrogen economy

Two-day webinar series presented by Gardner Business Media May 18 and 25 features a range of experts that will examine emerging hydrogen demand and the role composites will serve in this space.

-

NIAR’s ATLAS lab to install Cevotec SAMBA Pro system in 2021

The new system will open multiple options for evaluation and development based on Fiber Patch Placement technology, including material characterizations, application and process development, prototyping and testing.

-

Cevotec SAMBA Pro Prepreg system added to FPC technology portfolio

Installation of the automated Fiber Patch Placement system in Fraunhofer IGCV’s Fiber Placement Center serves active technology and application development.

-

The untapped potential in Formula 1 composite manufacture

Formula 1’s midfield teams are struggling to bridge the gap to their better resourced frontrunning counterparts. Could Industry 4.0 composites manufacturing automation level the playing field?

-

Cevotec upgrades SAMBA Fiber Patch Placement cells for production of large aerostructures

New features enable increased efficiency for curved structures using biaxial and quasi-isotropic laminates.

-

Cevotec, Fuji sign exclusive sales partnership for Japan and Thai markets

Japan-based Fuji Industries has exclusive rights to sell Cevotec products in the region, including Fiber Patch Placement composites automation technology.

-

Cevotec scales up Fiber Patch Placement technology for large aerostructures

The SAMBA Step L automated fiber placement system can place patches of material up to 50 times larger than previous FPP systems.

-

Cevotec system saves time, material in hydrogen storage vessel production

The company’s SAMBA-series fiber patch placement technology applies carbon fiber patches to the dome area to produce storage vessels for fuel cell electric vehicles.

-

CAMX 2019 exhibit preview: Cevotec

Cevotec will showcase automation processes for building complex composites at CAMX 2019.

-

Cevotec’s Fiber Patch Placement wins Industry of the Future award

The additive fiber layup technology enables automated production of complex fiber composites.

-

JEC World 2019: Cevotec engine nacelle demonstrator

Automated layup of multiple materials onto honeycomb core for 3D parts proven with Safran Nacelles collaboration.

-

SAMPE Summit 19 Paris

SAMPE Europe hosted its annual summit at Pullman Hotel Paris Tour Eiffel on March 11, prior to JEC World 2019.

-

The Fiber Placement Center of SGL Carbon and Fraunhofer IGCV add Cevotec and Coriolis Composites as partners

Cevotec and Coriolis Composites will contribute their own fiber placement and automation technologies to the FPC facility, which recently celebrated its one-year anniversary.

-

Fiber Patch Placement wins JEC Innovation Award in Seoul

Featuring a multi material feeding unit, Cevotec’s SAMBA Multi automates the time- and cost-intensive multi-material lay-up of aerospace sandwich components.

-

FPC to explore new production concepts for lightweight components

SGL Carbon and Fraunhofer IGCV have officially opened a new Fiber Placement Center in Meitingen, Germany.

-

Cevotec extends Fiber Patch Placement to sandwich structures, large aerostructures and enables combining with AFP

Automated preforming and layup process addresses core materials, as well as both continuous AFP and patch FPP reinforcements.

-

Composite Application Center launches in Singapore

An international group of companies has announced the launch of a Singapore based Composite Application Center to support the composites industry through combined expertise and facilities.

-

Cevotec and Composite Automation announce partnership agreement

The two companies join forces to meet the demand for automation solutions of North American composite manufacturers.

-

JEC World 2018 preview: Cevotec

Scalable SAMBA systems now ready for prepreg

-

Fiber Patch Placement at scale

SAMBA automated cells now offered in Step, Pro and Scale models, for 3D preforming dry fiber and prepreg at rates up to 15-100 kg/hr.

-

Cevotec dry-fiber bindered tape available for automated placement

Manufacturer of SAMBA automated placement systems offers high-quality material aimed to make series CFRP production economical for non-aerospace applications.

-

Preforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

-

Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

-

Exclusive preview of SAMBA preforming demo

Cevotec unveils its Artist Studio software and automated SAMBA preforming cell at JEC World 2017.

-

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

-

Fiber patch preforms help tailor kiteboard performance

Automated means for laying fiber only where needed offers new potential to fine-tune torsional stiffness and flexibility to board and rider styles.

-

Automated preform process boosts properties and cuts cycle time

Fiber Patch Placement (FPP) achieves optimized fiber orientation for up to 150% increase in stiffness and reduced cycle time, weight and material waste.

-

Automation and rapid processing dominate at JEC Americas

Highlights include Fiber Patch Preforming, automated potting and insert equipment and processes delivering composite parts in minutes.