AREVO Inc.

2090 Duane Ave.

Santa Clara, CA 95054 US

408-780-3993

arevo.com

About AREVO Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

AREVO Inc. Supplies the Following Products

- Other thermoplastics fabricating services

Editorial, News, and Products

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Two-time F1 champion Fernando Alonso, SimplyEV debut Kimoa e-bike at Miami Grand Prix

The Formula One driver’s sustainable mobility Kimoa brand is debuting its fully customizable carbon fiber e-bike powered by 3D printing firm Arevo.

-

Arevo debuts custom, 3D-printed composite scooter

Scotsman is a direct-to-consumer, tailor-made electric kickscooter with continuous carbon fiber/thermoplastic unibody frame, handlebars, stem and baseboard.

-

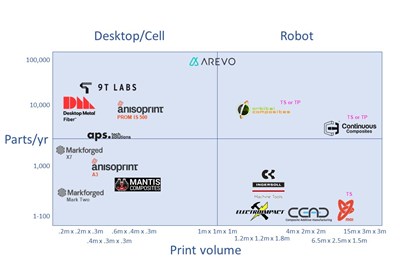

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

-

Arevo introduces high-speed AM system, closes Series B financial round

The financing round and high-speed AM system for large continuous carbon fiber composite structures follow Arevo’s 3D-printed bicycle campaign.

-

Arevo launches direct-to-customer 3D-printed bicycle

The Superstrata brand features a fully unibody carbon fiber/polyamide frame manufactured using Arevo’s direct deposition additive manufacturing process.

-

Construction of new Arevo composite 3D printing facility announced

The continuous fiber 3D printing specialist also named new executive leadership to support its growth plans.

-

Top composites news stories of 2019

The top 10 most viewed composites news stories of 2019.

-

Arevo, AGC Inc. partner to provide 3D-printed composite parts manufacturing services in Japan

AGC will provide a manufacturing as a service platform using Arevo’s Aqua 3D printer, which prints aerospace-grade CF/PEEK thermoplastic composite parts.

-

On the road with CompositesWorld

CW Senior Editor Scott Francis offers a recap of recent composites industries events including CAMX 2019 and SPE ACCE 2019.

-

Arevo to produce Pilot 3D-printed composite bike frames

The carbon fiber composite unibody bike frames were unveiled at Eurobike 2019.

-

Arevo introduces 3D-printed carbon fiber unibody bike frame and rim

Arevo will display its 3D-printed carbon fiber unibody production bike frame and 3D-printed thermoplastic rim at Eurobike 2019.

-

CAMX to host Additive Manufacturing Workshop for Composites

Co-located with CAMX, the event explores the connection between AM and continuous fiber reinforcement.

-

Emery launches 3D-printed eBike frame

The Emery ONE, the world’s first 3D-printed eBike, was developed in collaboration with Arevo, Franco Bicycles and Bosch.

-

Moving continuous-fiber 3D printing into production

With patents proliferating and production applications emerging, 3D printing with continuous fiber reinforcement is poised for significant market growth.

-

3D printing is missing the third dimension

Emerging processes like continuous fiber manufacturing, in-situ consolidation and tool-less manufacturing are bringing composite 3D printing into the third dimension.

-

AREVO launches battery-assisted 3D printed carbon-fiber frame bike

Company partners with Oechsler on a second application demonstrating its software-controlled additive manufacturing process.

-

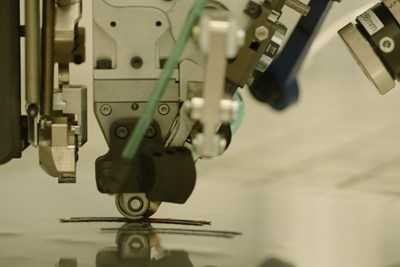

Arevo in 2018: Industrialized production of continuous fiber 3D-printed parts

With new CEO and $12.5 million in B-series financing, Arevo will have eight direct energy deposition (DED) cells attacking its parts production backlog by year-end.

-

Arevo composite additive manufacturing: the future of AFP?

Its multi-axis, continuous fiber technology eliminates tooling, matches strength of titanium parts at 1/3 the weight and cuts part cost vs. hand layup/autoclave cure by a factor of 5.

-

Additive manufacturing comes to composites fabrication

The use of continuous fiber in additive manufacturing systems is not trivial, but it is being done. As this fabrication technology evolves and matures, options for applying it in everything from automotive to aerospace to consumer composites will expand tremendously, creating a host of new opportunities for the composites industry. Read here for who is providing what kind of additive manufacturing technology for use in composites fabrication.