SABIC Innovative Plastics

SABIC

Europaboulevard 1

PO Box 5151

Sittard, 6130 PD NL

31 46 7222 222

sabic.eu

About SABIC Innovative Plastics

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

SABIC Innovative Plastics Supplies the Following Products

- CAD/CAM/CAE design

- Finite element modeling/analysis (FEM/FEA)

- Materials analysis

- Polypropylene (PP)

- Product design

- Thermoplastic, long fiber-reinforced (LFRT)

Editorial, News, and Products

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

SPE Automotive Division names finalists for 52nd Automotive Innovation Awards

Finalists display a variety of plastics and composites innovations. Winners will be announced Nov. 8, 2023, during the 52nd SPE Automotive Innovation Awards Gala.

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

SABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

-

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

-

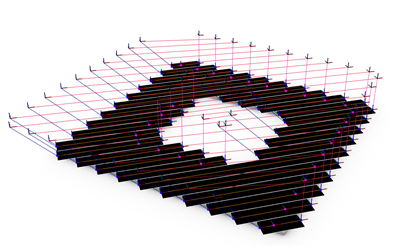

Increasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

-

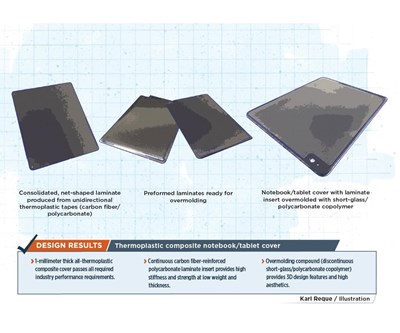

Consumer electronics: hybrid composite covers

Study demonstrates feasibility of thermoplastic composites, high-speed production process.

-

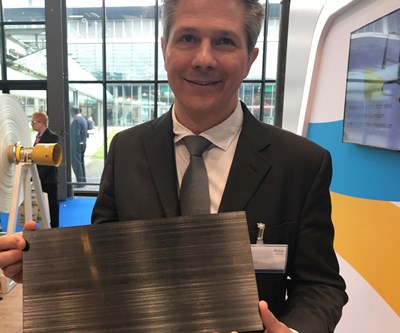

SABIC's innovations of scale

SABIC at JEC World 2019 offered a virtual reality-based peek at its new Digital Composites Manufacturing line — a collaboration with Airborne aimed at automated, large scale laminate production of thermoplastic composite parts.

-

CW Talks: Highly automated thermoplastic laminate production

The latest episode of CW Talks: The Composites Podcast, explores the collaborative development of a new thermoplastic laminate by SABIC, Airborne and Siemens.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

JEC World 2018: Highlights

You will read more about what we discovered at JEC World 2018 in the coming weeks and months, but for now this is a quick review of some of the highlights from the world’s largest composites trade show.

-

Airborne, Siemens and SABIC partner to mass produce thermoplastic composites

Flexible, automated production lines, featuring radically low conversion costs, aimed at millions of parts/yr — CW’s interview with all three companies.

-

Automated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

-

3D printed tools are in production at Dassault Falcon Jet

The trend of employing polymeric additive manufacturing (AM) or 3D printing for composite tooling is growing.

-

JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

-

Plant Tour: Tri-Mack Plastics Manufacturing, Bristol, RI, US

Precision thermoplastics parts manufacturer expands into hybrid composites to help meet OEM demand for higher performance while trimming weight, cost and lead times.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

Bioresins: Not a tsunami, but more like a rising tide

This excerpt from an upcoming article in CW magazine shows that a lot of investigation is happening, and some promising applications are developing.

-

Looking to lighten up aircraft interiors? Try natural fibers!

Aircraft OEMs are striving to make their products more efficient, with improved engines and ever-increasing use of composite materials, including in aircraft interiors.

-

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

-

3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

-

3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

-

Additive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

-

Fiber reinforcement forms

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

SPE’s ACCE 2014 preview

Automotive composites a hot topic in the Motor City.

-

ACMA COMPOSITES 2013 review

Once again, cautious optimism, an abundance of revealing research and a parade of notable new products are ACMA convention keystones.

-

Materials characterization: Faster cheaper, better

Ford couples commercial codes to analyze auto interior parts more accurately.

-

2012 JEC Europe Highlights

JEC’s annual Paris exhibition reports impressive attendance figures as exhibitors tout big news.

-

Carbon fiber market: Gathering momentum

All signs point to increasing demand from many market sectors. Will capacity keep pace?