Hennecke Inc.

1000 Energy Drive

Bridgeville, PA 15017 US

724-271-3686

henneckeinc.com

About Hennecke Inc.

For more than 70 years, the Hennecke Group, with headquarters in Sankt Augustin, Germany, has been producing high-quality machines, plants, and systems for all core technologies of polyurethane processing.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Hennecke Inc. Supplies the Following Products

- Automated fiber placement systems

- Automotive, body panels & substructures

- Automotive, interior (seats, IPCs, floor panels, etc.)

- Automotive, underhood

- Carbon/carbon composites

- Continuous laminating machines

- Education/Training

- Foam application equipment

- Laminate panels, with core

- Other composite structures

- Other primary manufacturing equipment

- Pressure vessels

- Pultrusion equipment, thermosets

- Reaction injection molding equipment (RIM, RRIM, SRIM)

- Repair services, equipment and machines

- Resin transfer molding equipment (RTM)

- Roll-forming machines

- Spray booths

- Spray guns

- Testing, materials

Editorial, News, and Products

-

Hybrid injection technique achieves aesthetic, resilient product surfaces

CAMX 2023: Hennecke, in partnership with Engel, will be displaying how the clearmelt method, a process that enables users to manufacture durable, scratch-proof and self-curing polyurethane surfaces for automobile interior and exterior components.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

-

People in Composites: December 2020

CW’s December people roundup include new appointees for Cincinnati Inc., Polygon Composites, Exel Composites, Vectorply, Northrop Grumman and more.

-

FRIMO, Hennecke form strategic partnership for automotive applications

The companies will combine their core competencies with a focus on polyurethane and other materials applications for the production of passenger vehicles.

-

Hennecke Group announces company reorganization plans

Under the Hennecke 2.0 name and new CEO Thomas Wildt, the polyurethane group has reorganized its companies into four “centers of excellence.”

-

Hennecke Group North American headquarters moves to new facility

The new facility includes a research and development laboratory, a modern parts warehouse and areas for machinery repair and mixhead rebuilding services.

-

Hennecke, PGTEX cooperate on HP-RTM, wet shot technology

Hennecke has been awarded a contract for a combined production plant for manufacturing wet shot and HP-RTM applications by Chinese composites company PGTEX.

-

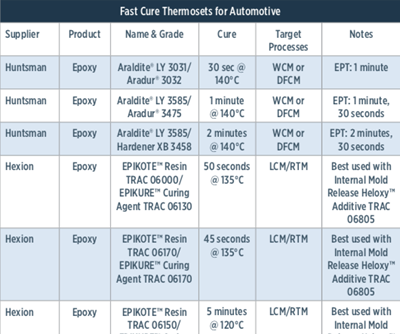

Fast and Faster: Rapid-cure resins drive down cycle times

New systems include sub-1-minute cures ideal for higher automotive production volumes.

-

500,000 parts per year? No problem!

BENTELER-SGL develops fully automated HP-RTM production of the weight- and space-saving composite leaf spring for Volvo’s multi-model SPA global platform.

-

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Form + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

-

Mubea Carbo Tech: High-quality auto composites go high-volume

Known for its precision and technical acumen in CFRP motorsports structures, MCT draws from its steel auto parts parent to push high-performance and industrial production to new plateaus.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

-

Processing within the PUR cure window

Composite Spray Molding enables volume production of fiber-reinforced polyurethane sandwich structures for auto interiors. Are Class A exterior parts next?

-

COMPOSITES 2012 Highlights

As ACMA’s annual conclave convened in North America’s gambling capital, show exhibitors and attendees placed their bets on better days.