WH Lipex introduces single fiber applicator for glass fiber sizing implementation

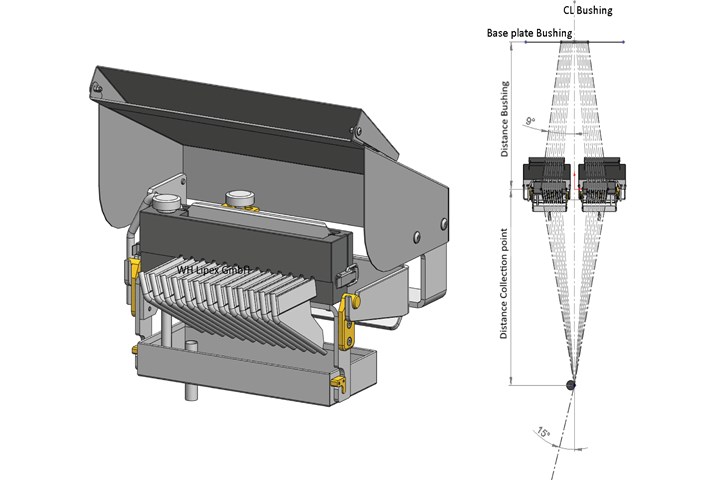

Coating module individually displays glass fibers for complete fiber wetout and improved bonding capabilities.

Photo Credit: WH Lipex

WH Lipex (Munich, Germany) part of Woollard & Henry Group (Aberdeen, U.K.) and a fiberglass technology company, introduces the single fiber applicator, a coating module that enables manufacturers to apply sizing to individual glass fiber strands.

Fibers are no longer in bundles, but are instead individually displayed, ensuring all individual filaments are better enclosed with wetting additive. This performance is said to significantly increases the sizing amount on the fibers, improving their bonding capabilities.

Further, WH Lipex says the applicator’s main advantages include increasing the end product’s mechanical properties, thus offering new possibilities for weight and cost reduction.

Related Content

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.