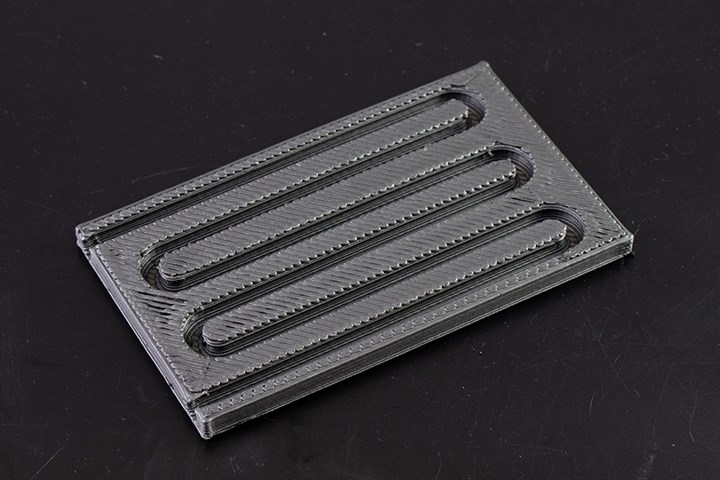

TCPoly thermal conductive filaments for 3D printing

The Ice9 product offerings are composed of carbon-based fillers and ceramic filler parts.

Source | TCPoly

Thermal solutions provider, TCPoly (Atlanta, GA, U.S.) features the developments of its TCPoly Ice9 thermally conductive filaments, the first heat-conducting plastics for open source FDM 3D printers. Composed of a mix of carbon-based fillers and ceramic filler particles, the 3D printing filaments are said to retain a thermal conductivity up to 50 times higher than standard filaments (10 W/mK), such as Acrylonitrile-butadiene-styrene (ABS), polylactide (PLA), Nylon, PETG. When combined with the design freedom of 3D printing, TCPoly says its filaments can be used to make high-performance heat transfer products for electronics thermal management, heat exchangers, mold tooling and other industries.

TCPoly offers three varying Ice9 filament products. Flex (TPE), said to have the highest thermal conductivity at 8 W/mK and high toughness, is available in electrically insulated grades. Retaining a tensile strength of 15 MPa, maximum temperature use holds at 110ºC. Rigid (PA6) is a nylon-based filament with the second highest thermal conductivity at 4 W/mK, a tensile strength of 30 MPa and overall high modulus and temperature stability. Finally, Aero (PEKK), in addition to its thermal conduction of 2.5 W/mK, is flame-retardant with a temperature stability above 250ºC and a tensile strength of 100 MPa.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

.jpg;maxWidth=300;quality=90)