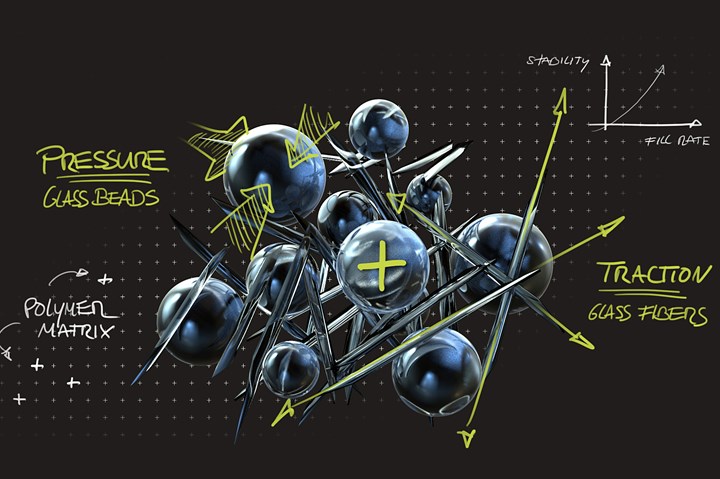

Swarco glass filler beads enable 3D printing material optimization

A range of tailor-made glass filler beads for additive manufacturing help improve the properties of 3D printing base materials, including composites.

A range of tailor-made glass filler beads developed by Swarco Advanced Industry Systems (Amstetten, Austria) enable the properties of 3D printing base materials to be individually modified and optimized according to individual parameters. Adding them simultaneously increases the hardness and creep behavior of the basic material, according to Swarco. Glass filler beads give molded parts a higher density and contribute to reducing material costs, thanks to the highly efficient production process with a small carbon footprint. They are also ideal solutions in the use of 3D-printed parts.

Swarco Advanced Industry Systems is part of the international Swarco Group and uses the universal benefits of glass beads for special industrial applications. What began in 1969 as a business producing small reflective glass beads for road markings has evolved into a leading manufacturer of micro glass beads, with production sites in Europe and the U.S. Micro glass beads serve as a high-grade filler material in industrial applications, as well as the composites industry, and as a blasting abrasive for surface treatments.

Related Content

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.