Solvay launches epoxy prepreg for aerostructures compression molding

Solvay Composite Materials has launched CYCOM EP2750, a new highly drapable epoxy prepreg designed specifically for the compression molding of high-quality, high-rate, cost-effective primary and secondary aerostructures.

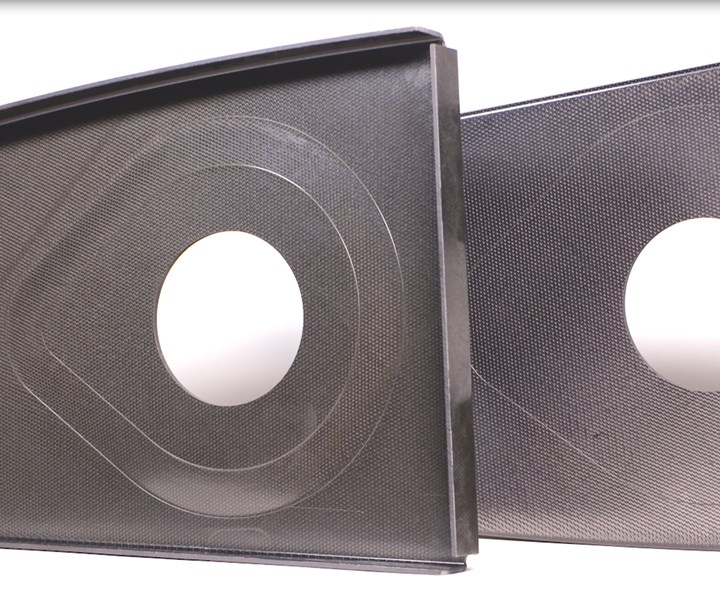

Rib-like parts fabricated with Solvay’s CYCOM EP2750 epoxy prepreg. Source | Luchini, T., Rodriguez, A., Rogers S., Bras A., Whysall, A., Russell, R., Lucas, S., Hahn, G. "Spring Frame Press Fabrication of Aerospace Production Components,” SAMPE 2019.

Solvay Composite Materials (Alpharetta, Ga., U.S.) announced on Feb. 24 that it has launched CYCOM EP2750, a new highly drapable epoxy prepreg designed specifically for the compression molding of high-quality, high-rate, cost-effective primary and secondary aerostructures. The resin can be processed via compression molding only, compression molding with freestanding post-cure, or autoclave cure and offers takt times as short at 15 minutes.

Solvay officials say development of CYCOM EP2750 was stimulated by demand for an epoxy prepreg that allows fabricators to provide high-rate, reliable, cost-effective parts manufacture at aerospace quality. The goal of the prepreg is to enable manufacture of composite parts that are cost- and performance-competitive with machined aluminum.

Solvay points to two aerospace market trends that are likely to benefit significantly from CYCOM EP2750. First, single-aisle replacements for the Boeing 737 and the Airbus A320 aircraft are each expected to be manufactured at or close to 100 units per month. Second is the burgeoning urban air mobility (UAM) market, comprised of small, point-to-point, manned and unmanned aircraft. These likely will be manufactured at rates numbering 3,000-5,000 units per year and, like larger commercial aircraft, will require materials and processes qualified for aerospace application.

For commercial aircraft, CYCOM EP2750 is targeted toward use in access panels, blocker doors, brackets and clips. For UAM and UAV applications, the prepreg is targeted toward use in bulkheads, ribs, fuselage sections, brackets and clips.

Representatives of Solvay anticipate that the preferred process for CYCOM EP2750 will be isothermal press cure, in which the layup is preheated, inserted into the mold, pressed, removed from the mold and then trimmed. This “hot in/hot out” process offers a 95% degree of cure at part removal and has a takt time of 60 minutes at 170°C, or 30 minutes at 190°C. The resin is said to offer low risk of exotherm even at high process temperatures.

Alternatively, CYCOM EP2750 can be pressed to 80% degree of cure, and then post-cured (freestanding) outside the mold. Using this process, parts can be removed from the mold after 15-45 minutes, depending on the cure temperature. For autoclave cure, the prepreg must be ramped up to 177°C for a 30-minute dwell, followed by cool-down. Total take time for this process is 120-180 minutes. Finally, CYCOM EP2750 is compatible with Solvay’s new Double Diaphragm Forming (DDF) process.

Complex part manufactured with Solvay CYCOM EP2750 epoxy prepreg. Source | Solvay

Mechanical properties of CYCOM EP2750 include a service temperature of 132°C, a dry Tg of 197°C and a wet Tg of 168°C. Hot/wet open hole compression strength is 40.5 ksi; room temperature open hole compression strength is 50.5 ksi. Solvay says the National Center for Advanced Materials Performance (NCAMP) at Wichita State University (Wichita, Kan., U.S.) has begun qualification of CYCOM EP2750 that is expected to be completed before the end of 2020.

CYCOM EP2750 is currently being prepregged with Solvay’s 3k-tow, 8-harness Thornel T650 carbon fiber reinforcement. Under development and scale-up are product versions using a 2x2 carbon fiber twill and a unidirectional carbon fiber tape.

CYCOM EP2750 is being formally introduced to the market on the Solvay stand (Hall 5, M41) at the JEC World 2020 exhibition, March 3-5 in Paris. Parts made with CYCOM EP2750 will be on display.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)