PRF Composite Materials releases RP542-4 toughened prepreg system for UD and woven fabrics

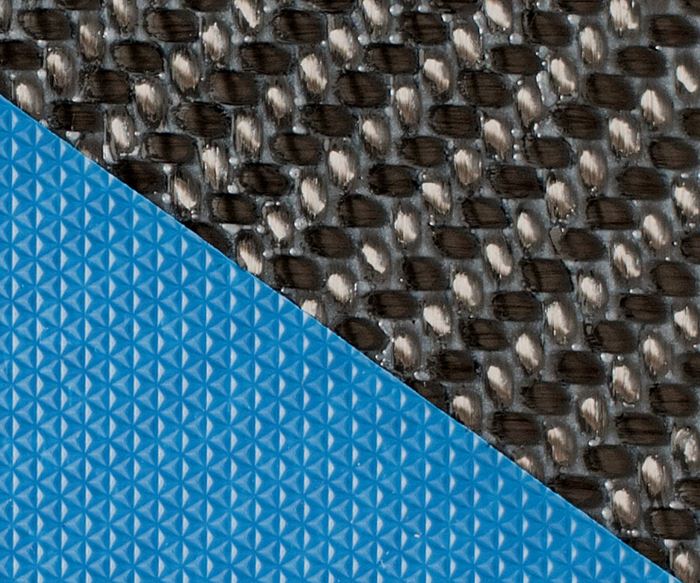

PRF Composite Materials’ RP542-4 is its latest epoxy prepreg system for unidirectional and woven carbon fiber fabrics.

PRF Composite Materials (Dorset, U.K.) introduces RP542-4, its latest epoxy

prepreg system for unidirectional (UD) and woven carbon fiber fabrics. RP542-4 has been designed as an intermediately toughened system to complement the company’s RP542-1 and super-toughened RP549 systems.

According to the company, the system has exhibited excellent tensile, compressive, flexural and interlaminar properties through mechanical testing, and has shown a coefficient of thermal expansion (Tg) of 138°C after curing at 120°C. The onset Tg can reportedly be improved by 20°C to 120°C after postcuring at 140°C for 2 hours. The system has an outlife of 60 days at 20°C. RP542-4 is available on 300-gsm and 600-gsm unidirectional carbon fiber as well as on a variety of fiber types in PRF’s range of high-quality woven fabrics.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

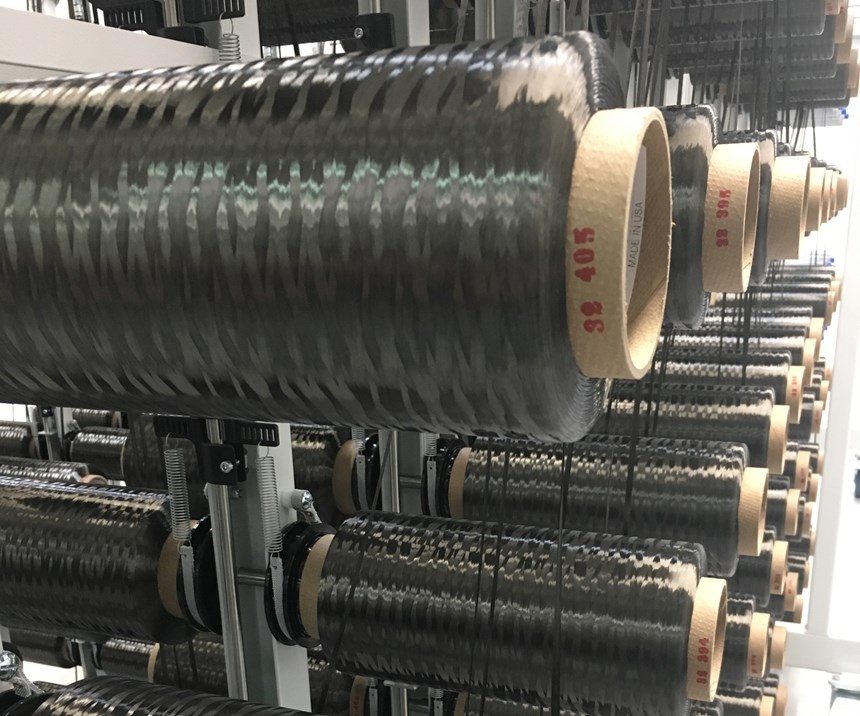

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

.jpg;width=70;height=70;mode=crop)