ITA RWTH Aachen University launches fiber-coating line, carbon fiber research

The Institut für Textiltechnik of RWTH Aachen University is presenting innovations in glass and carbon fiber production at the joint stand of the Aachen Center for Integrative Lightweight Construction.

Source | ITA

Editor’s note: CompositesWorld received several new product and technology announcements ahead of JEC World 2020, which had been scheduled for March 3-5. Although that exhibition was postponed to May, CW is now publishing the announcements we received. This is one of them.

The Institut für Textiltechnik of RWTH Aachen University (ITA, Aachen, Germany) is presenting innovations in glass and carbon fiber production at the joint stand of the Aachen Center for Integrative Lightweight Construction.

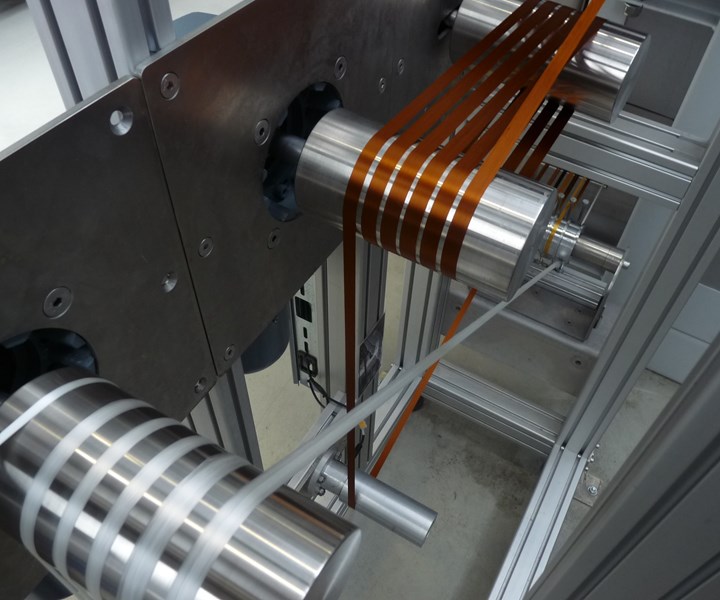

Live demonstrations of multi-fiber coating system

Live at the booth, ITA is demonstrating how its multi-material fiber coating line coats or impregnates rovings made of various materials, producing towpregs, also known as pre-impregnated rovings, from thermoplastics and carbon fibers. Towpregs can be processed by winding or braiding. Examples of use include in drive shafts in the automotive or the aerospace industry.

The system, ITA says, has a wide range of applications and allows a fast output. With a maximum processing temperature of 400°C, it also allows high-temperature thermoplastics to be processed, and quickly tests with a variety of materials on a laboratory scale. The current production speeds are 5 m/min, depending on the material used and the configuration of the system, and ITA says upscaling to industrial scale is possible. The plant can process thermosets and thermoplastics.

With this line, towpregs with circular cross-sections of up to 5 mm in diameter and tape-like geometries of up to 20 mm in width can be produced at a production speed of 5 m/min, depending on the material used and the configuration of the line.

Carbon fiber production research

In addition, ITA is showcasing its production of carbon fibers, one of its core research areas. ITA has a continuous pilot-scale carbon fiber production plant with a production capacity of less than one ton per year. Due to its comparatively small size and the resulting low material input, the plant is ideally suited for the development of new stabilization and carbonization profiles and the testing of new fiber sizings, ITA says.

The current main goal of research in carbon fiber production is to shorten the stabilization time from an initial 50 minutes to approximately 21 minutes. The resulting fibers are at the level of a Toray T700 carbon fiber.

Another approach to reduce the cost of carbon fibers is the use of alternative raw materials such as polyethylene (PE). This can reduce the carbon fiber price by about 50%, ITA says. Due to the existing spinning and sulfonation plants ITA is one of the leading research institutes dealing with the production of cost-effective carbon fibers based on polyolefins.

Textile technology and photonics

Carbon fiber-reinforced (CFRP) components are often assembled by fasteners that are glued into the cured and drilled CFRP component. According to ITA, the integration of the fasteners into a textile preform and an additional curing process to produce the final CFRP component can shorten production process chains and can increase the performance of the joint by at least 50%. This requires high-precision cutouts in the textile for the fasteners.

In the NRW-based project CarboLase, funded by OP.EFRE, laser material processing is integrated for the first time into an automated preforming process. A novelty in the process is the use of the material-friendly ultrashort pulsed laser, which processes the textiles without damaging them thermally.

By combining the technologies in a flexible robot cell, just-in-time production of CFRP components with integrated fasteners is now possible independent of component geometry and batch size. With the new process chain, demonstrators were produced fully automatically. A demonstrator in the form of a B-pillar segment with integrated fasteners is shown in the following figure.

This technology was developed by the Institut für Textiltechnik of RWTH Aachen University, short ITA, in collaboration with its partners AMPHOS GmbH, Kohlhage Fasteners GmbH & Co. KG, LUNOVU Integrated Laser Solutions GmbH and the Fraunhofer Institute for Laser Technology ILT.

High-speed prepreg filament winding

ITA is working with many industries on filament winding technology, including its novel multi-filament winding technology. The main advantage to this method, ITA says, is that many fibers (facility at ITA with 48 fibers) can be wound simultaneously, increasing the processing speed by a factor of 50 and enabling a coverage of 100% in a single pass.

The working speed has been increased further with the development of high quality prepregs through the ZIM project MFWOptiPreg with the company F.A. Kümpers GmbH & Co. KG. The optimized tack (stickness) and fiber breakage, high winding speeds and quality products can be achieved. Filament winding has an advantage of orienting the fibers in the desired direction (0°≤θ<90°).

As an example for quality products, these prepregs have been tested for pressure vessel and torsion shaft manufacturing, ITA says. The developed prepreg is already available in the market.

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;width=70;height=70;mode=crop)