Injection Molding: At NPE, U.S. Debut of Arburg’s Largest Machine Yet in a Brand-New Design

Besides a brand-new machine design, Arburg will present cells molding automotive composites, medical, LSR, and packaging applications, as well as Industry 4.0 multiprocess integration and Freeformer 3D printing.

Arburg’s “big reveal” at K 2016 is now coming to NPE2018 as the U.S. launch of its largest machine ever and the first of a brand-new design with a sophisticated new control. The Allrounder 1120H (photo) has a 650-metric-ton clamp (730 U.S. tons, 30% larger than any previous Arburg machine) with 1120 mm tiebar spacing (20% larger than other Allrounders) and 1050 mm stroke. Dry-cycle time is 2.4 sec. This hybrid press has an electric toggle clamp powered by twin servos, plus servo-hydraulic injection with a gas accumulator. Electric ejection is standard, with hydraulic optional. The sleek new design encloses all electric, hydraulic, pneumatic, lubrication, and temperature-control systems within the machine frame. Safety gates and injection unit run on linear guides. Integrated fold-out steps provide access to the mold area.

Its new Gestica controller has a pivoting and height-adjustable operator panel with a smooth glass front that resembles a tablet computer and accepts multitouch/gesture commands. The 15.6-in., full-HD screen has a new EASYslider element that allows fingertip dynamic control of machine movements during setup. Motions can be speeded up or slowed down with the swipe of a finger on the on-screen bar. (A second machine of this new design with the Gestica controller is the 500-m.t. Allrounder 920H, which arrived at Fakuma 2017.)

The Allrounder 1120H will be molding a PP folding step stool, molded in an eight-cavity family mold and snapped together in an adjoining cell with a pair of six-axis robots. The parts will be demolded by a Multilift V Cartesian robot with 88-lb payload capacity (also introduced at K 2016).

Arburg (U.S. office in Rocky Hill, Conn.) will have a total of nine exhibits at NPE (booth W1325). Among the others will be:

• An electric Allrounder 570A producing wrist straps in LSR with two colors and durometers (70 and 30 Shore A), and assembling complete watch in a robotic cell.

• A dual-durometer LSR/LSR (70 and 30 Shore A) membrane for valves used in medical and automotive applications will be molded on an Allrounder 270A with a 0.1-oz micro-injection unit incorporating a 0.3-in. screw to produce one 0.0018-oz component, which is then overmolded using a servo-electric injector from Kipe Molds, Placentia, Calif. (kipemolds.com), which is integrated into the 1 + 1 cavity mold and the Selogica control system.

• A packaging version of the Allrounder 570H designed specifically for thin-wall molding, will produce four IML tubs from PP in a cycle time around 1.9 sec. The finished parts weigh 0.12 oz and have walls 0.0126 in. thick.

• In another cell, an electric Allrounder 470 A will mold two cups of medical-grade PP, each weighing just over 0.05 oz, in a cycle of 2.9 sec.

• For automotive, long-glass reinforced airbag housings will be molded with “fiber direct compounding” (FDC), whereby continuous glass rovings are fed into the injection barrel downstream of the feed opening. A side feeder with integrated cutter and a special screw and barrel permit customizing the fiber length and concentration. A weight monitor will display the consistency of shot weight.

• Insert encapsulation will be shown on a vertical rotary-table machine. Metal inserts will be fed to a plasma pretreatment station before overmolding with nylon 66.

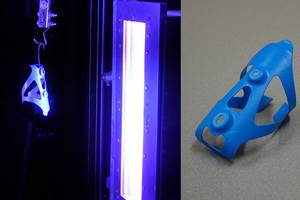

• In what has become a trademark exhibit for Arburg at major shows, Industry 4.0 networking capability will be demonstrated by molding individualized business-card holders and then barcode labeling them by laser marking, followed by custom decorating with Arburg’s Freeformer 3D printer.

• Another Freeformer exhibit will show that these machines now process not only amorphous resins like ABS, PC, and nylon 12, but also TPE and semi-crystalline materials like PP and PLA.

Related Content

JEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreCarbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

Read MoreDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

Read MoreToray rCF from Boeing 787 is incorporated into ultra-light laptops

Torayca-based aerospace components have successfully been repurposed into the Lenovo ThinkPad X1 Carbon Gen 12, highlighting the ongoing application of recycled composites.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)