Covestro establishes CFRTP as "a material class of its own"

Trademarked as Maezio, Covestro claims continuous fiber reinforced thermoplastic composites “outperform metals,” offering advantages in aesthetics, lightweight and robust process flexibility.

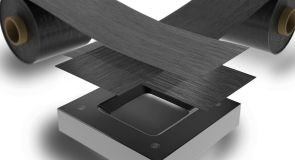

My April blog “Continuous fiber thermoplastics are smart for world’s largest appliance manufacturer” discussed the development of a high-end production air conditioner using CFRTP composite materials by supplier Covestro and the world’s largest appliance company Haier. Now Covestro has trademarked these materials as Maezio, which include carbon or glass fibers impregnated with polycarbonate (PC), thermoplastic polyurethane (TPU) or other thermoplastic resins. Covestro produces unidirectional reinforced tapes and sheets at its production site in Markt Bibart, Germany.

|

|

Maezio continuous fiber reinforced thermoplastic (CFRTP) materials are produced by Covestro in Markt Bibart, Germany. SOURCE: Covestro

“The brand gives us a clear and strong identity to further expand our expertise in thermoplastic composites,” says David Hartmann, Co-CEO for CFRTP composites alongside Dr. Michael Schmidt. “We believe the new brand can truly bring value to next-generation products across industries by delivering a combination of lightweight construction, specific strengths and finishes at a scale unreachable by advanced materials today.”

The variety of finishes Covestro is showing are indeed impressive. Covestro’s media page on Maezio features a video with interviews from multiple players along the supply chain who tout the material’s appealing aesthetics and design flexibility alongside its ability to break through the lightweight and low thickness boundaries of traditional metal and plastic materials.

|

|

Covestro’s Maezio CFRTP materials are strong, lightweight and aesthetic, able to be combined into a reportedly unlimited number of products, giving designers new creative opportunities. SOURCE: Covestro.

Mass production for multiple markets

Covestro claims that widespread propagation of advanced composites has been hampered by lack of cost-effective and scalable manufacturing processes. In its media and press releases, the company notes that composites also have been difficult to integrate into high-volume products, but Maezio materials are changing this:

These innovative materials are set to tap into the growing demand worldwide for strong and light materials that contribute to resource conservation and energy efficiency. From mobility and electronics industries to consumer goods and medical products, OEMs and part suppliers can benefit from the high-performance capabilities of advanced composites while enjoying cost-effective and scalable manufacturing solutions offered by Maezio.

|

|

|

|

SOURCE: Covestro

Maezio materials can reportedly be thermoformed with existing thermoforming tools at high yield rates and low cycle times for millions of parts per year. Other production technologies such as hybrid injection molding (overmolding), automated UD tape laying and automated fiber placement (AFP) can be easily integrated.

RocTool is working with Covestro’s Maezio products in its composites processing developments for the consumer electronics industry. SOURCE: Covestro

As thermoplastic composites, Maezio products can also be recycled at the end of their useful life, making them “a perfect example of what scalable and sustainable composite solutions look like in giving industries the material tools to push boundaries,” says Co-CEO for CFRTP Michael Schmidt.

Covestro reports that Maezio is attracting interest in diverse market segments including the electrical and electronics industry, automotive, medical technology, sporting goods, athletic shoes and consumer goods like household appliances, furniture and luggage.

Note that Solvay, Premium AEROTEC and Faurecia Clean Mobility have also recently announced efforts toward high-volume thermoplastic composites production.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreCycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Continuous fiber thermoplastics are smart for world’s largest appliance manufacturer

Haier uses Covestro CFRTP in Casarte line of “smart” air conditioners

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More