Carbon fiber will enable air taxi eVTOLs

Aircraft and autos have indeed faced CFRP production woes, but new tech opens door for both.

- Automotive

- Sheet Molding Compound

- Carbon Fibers

- Out of Autoclave

- Materials

- Fabrics/Preforms

- Adhesives

- ATL/AFP

- Processes

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Electric Vehicles

- Reinforcements

- Markets

- Injection/Overmolding

- Autoclave

- Compression Molding

- Ketones

- Additive Manufacturing

- RTM

- Advanced Air Mobility

This blog is in response to a Jan 2019 article in WIRED magazine, which claims carbon fiber composite production is holding back the development of electric vehicle (EV)/vertical takeoff and landing (VTOL) aircraft for the urban mobility and air taxi market. I’m going to debate this, but also offer some potentially disruptive new technology, so read through to the end.

Although I applaud the author for covering this rapidly emerging industry, and for pointing out the need for designing with manufacturability in mind, he is misleading at times, most likely because he is not very educated about the composites industry. For example:

“Today, no company on Earth makes more than 700 aircraft a year, a factor of complexity and the relatively modest market size.”

While that is technically true, Airbus is ramping to 60 A320 aircraft/month by mid-2019 and Boeing is on its way to 57 aircraft/month for the B737, also in 2019. For the A320, this means producing three 6.3-m-tall carbon fiber reinforced plastic (CFRP) vertical tail plane assemblies per day and also three 12.45-m-span CFRP horizontal tail plane assemblies per day.

Also, Airbus has been qualifying one technology after another — many using composites, and all aimed at 60-70 aircraft per month — for the next iteration of the A320, referred to as the A320 Neo Plus. These composites technologies span a portfolio including resin transfer molding (RTM), compression molding of sheet molding compound (SMC) and thermoplastic composites (TPCs) that have cycle times easily capable of 700+ aircraft per year. Some of the newest technologies in development are cutting CFRP part cycle times down from 4 hours to 15 minutes or less. Most of the new technologies that Airbus has qualified are heavily automated, as are the new assembly methods.

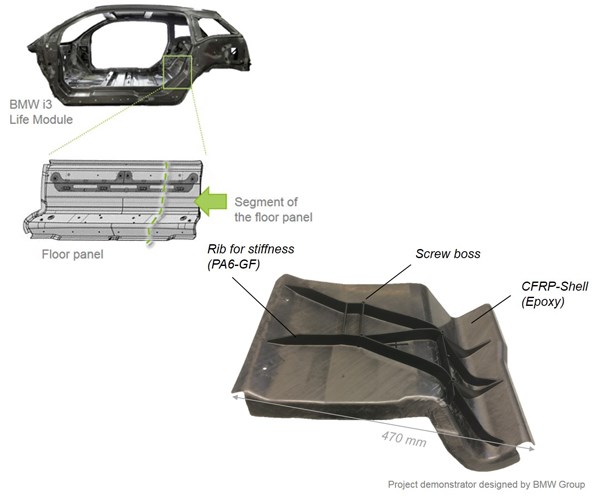

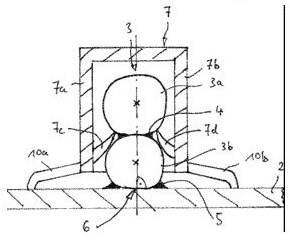

The automotive industry has also paved the way toward higher mass production than eVTOLs will require (WIRED cited projected demand of 23,000 vehicles by 2035). BMW is increasing production of its i3 and i8 models – both feature all-CFRP passenger cells — from 130 to 200 units/day and Audi supplier Voith Composites is producing the CFRP rear wall for the A8 at a rate of 150-300 units/day. Note that the BMW i3 and i8 modules are very similar to the airframe shown below for the Airbus Helicopters EC 135 — both manufacturers then fasten on exteriors and interior components to this frame.

The BMW i3 and i8 body frames are very similar to that of the Airbus Helicopters EC135.

SOURCE: Milestones of the Leading-Edge Cluster – Review and Future Prospects, MAI Carbon, pp 36-7 (top), BMW and Airbus Helicopter (bottom).

Meanwhile, the Audi A8 rear wall is made with a 5-minute cycle time using RTM and automated placement of dry carbon fiber tape, tailored in length and fiber orientation to meet specific loads, and varying from a base of 6 plies (1.5-mm-thick) up to 19 plies (3.7-mm-thick) where local reinforcement is added to meet high point loading. This single part provides 33% of the drive cell’s torsional stiffness at 50% of the weight vs. an assembly of three to five welded aluminum parts.

The 2019 Audi A8 features a CFRP rear wall made in 5 minutes from carbon fiber tape.SOURCE: Audi and Voith Composites.

Thermoplastics

But these examples are not even exploiting thermoplastic technology, favored as the choice for Boeing’s new mid-size aircraft (NMA), which is slated to be announced before 2Q 2019. Thermoplastic parts have been flying on aircraft since the 1990s, while development has continued, with Airbus and European Tier 1 suppliers prototyping ever larger wing and fuselage sections (with integrated stiffeners), scaling to full-size fuselage demonstrators this year. Note that thermoplastic composites also enable welding, giving further opportunities to eliminate fasteners and assembly.

Automated Dynamics, now part of Trelleborg Group, produced this full-size, integrally stiffened CF/PEEK helicopter tailboom in 2012 using in-situ consolidation during automated fiber placement, eliminating lengthy autoclave cycles as well as fasteners and adhesives.

SOURCE: Automated Dynamics, Trelleborg

The supply chain for TPC materials and processing has coalesced quickly over the past three years, with all of the major carbon fiber suppliers now producing thermoplastic tapes and low-cycle time overmolded parts demonstrated by multiple companies for both aerospace and automotive applications. Thermoplastic welding has also been demonstrated by multiple companies.

Excerpt from “Overmolding as enabler for composites, aerospace to automotive”, interviewing Scott King at composites fabricator CCP Gransden:

What about the perception that overmolding is very expensive, with high tooling costs? “Some perceive that part costs will run into the thousands,” King says, “but that’s not how we see it. It can be cost-effective, especially if you look at the complete life cycle because it removes assembly stages. You no longer need multiple different materials and inserts, but instead deliver just one integrated part to the line. We are also looking to further reduce the cost of overmolding. For example, many think the tooling will be £85,000-100,000 ($120,000-140,000) or more, but we have been able to utilize tooling that costs as little as £10,000-15,000 ($14,000-21,000) to produce complex, overmolded components.” … “We can make 1,000-1,500 parts per 24-hr shift,” he says, noting that the CF/PPS demonstration part was pressed/molded in 60 seconds.”

CCP Gransden has refined its one-step thermoforming and thermoplastic composite overmolding technology to produce lightweight, complex components with typically < 2-min cycle times, using a wide range of polymers and fibers. SOURCE: CCP Gransden

Newest Tech

But the technology has moved forward since 2014 to now include several interesting developments:

Thermoplastic-overmolded Thermosets

The OPTO-Light project at AZL Aachen demonstrated overmolded thermoplastic composite (TPC) ribs and clips onto a carbon fiber/epoxy composite part.

SOURCE: AZL Aachen

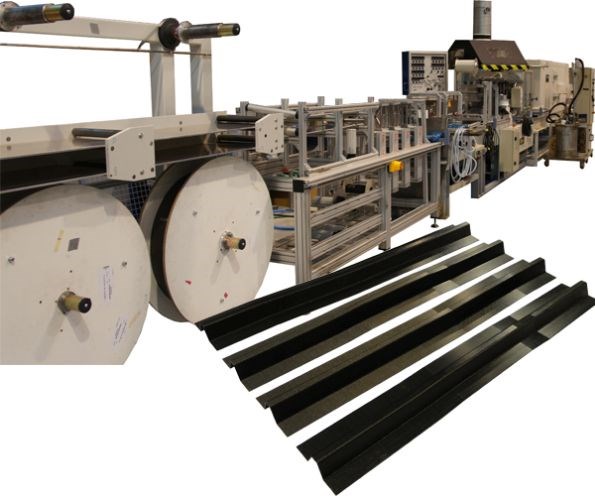

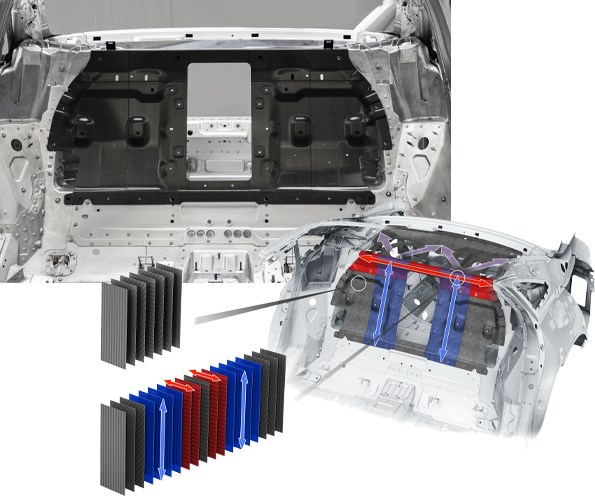

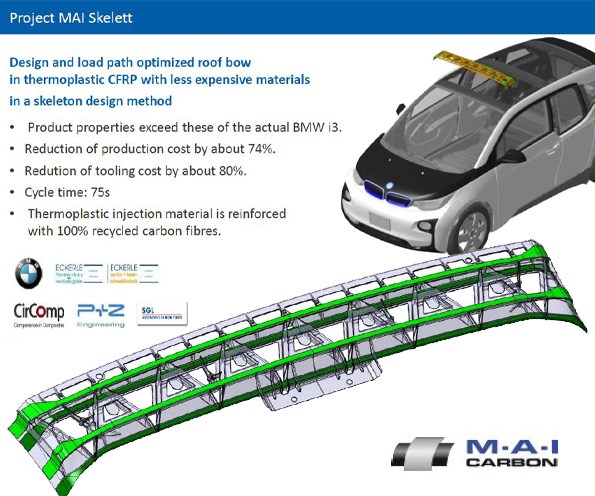

Overmolding + UD Load-carrying Pultrusions

MAI Skelett project has demonstrated overmolded TPC pultrusions in a two-step, 75-second process to produce a structural roof member/windshield frame that exceeds all BMW i3 part requirements while integrating attachments and clips, as well as changing crash behavior from brittle to ductile failure mode for increased BIW residual strength.

Project partner SGL Carbon now supplies carbon fiber with appropriate sizing for single-matrix solutions using PP or PA6 family, including pultrusions, organosheet and overmolding compound as well as design and process expertise for part development, the latter via their Lightweight Applications Center (LAC, Meitingen, Germany).

The MAI Skelett project demonstrated a BMW i3 roof structure redesigned using thermoplastic CFRTP pultrusions as a load-carrying skeleton, with CFRTP overmolding uniting them into a structure while integrated clips and fastening features. SOURCE: MAI Carbon.

Next-generation fastening

BMW — partner in both OPTO-Light and MAI Skelett projects — has developed a patented, high-precision fastening system which comprises a ball and clip, analogous to how LEGO blocks attach. The clip receives the ball and may be overmolded onto the body structures as we have seen in multiple examples. The ball may be welded, injection molded or 3D printed onto the body or interior panel, enabling it to be “snapped” onto the structural frame and also removed. The patent explains that the ball and clip can be designed such that the panels can be slid on and off longitudinally, and/or also such that pull-off force to remove is 1.5 to 4.5 times larger than the push-on force to attach.

This fastening system has already been unrolled in the hybrid composite, aluminum and steel body construction of the current BMW 7 Series and is now also used in the BMW 5 Series and BMW 6 Series Gran Turismo, according to Editor Alexander Stark in his article, “Smart Joining and Measuring are the Basis of BMW’s Lightweight Material Mix”.

BMW’s new patented, high-precision fastening system uses injection molded or overmolded clips (bottom) and 3D printed balls (top) without fasteners, drilled holes or adhesive. The bottom images show how this system enables custom 3D printed interior trim to be “snapped on” as part of the 2019 MINI Yours Customised program.

SOURCE: Patent DE 10 2013 214 269 B3 (top)

https://www.youtube.com/watch?v=1pyxNKw-nf8 (bottom)

Back to the WIRED article and its uninformed claims:

“Carbon fiber is wondrous for its light weight and strength, but it’s a pain to make. The time-intensive process includes laying up resin-soaked carbon-fiber sheets in molds, trimming the pieces after they’ve cured for hours in an oven, and bonding components together.”

It is true that this method of CFRP production has been used for many years, but it is also true that both aircraft and automotive manufacturers have already switched to more automated, near-zero waste materials and processes, as well as thermoplastics with proven advantages in eliminating fasteners, enabling recyclability/recycled content and repairability.

In the end, the WIRED author contradicts his whole thesis because eVTOL pioneer ICON plans to not only move forward with its CFRP airframe but also manufacture parts for larger aircraft. Carbon fiber obviously is not going to ground eVTOLS but instead is already playing a key part in companies pushing forward clever engineering for a wide range of future vehicles, both in the air and on the road. Using the latest in technology makes sense because all of these new vehicles have to be certified anyway.

One key point was made in the article by BetaTechnologies CEO Kyle Clark:

“If we throw a design over the wall and don’t understand the ‘art of the possible,’ then we miss the opportunity to make the entire design as simple and elegant as we can, …”

Blue Force Technologies CEO Scott Bledsoe also stressed the importance of having aerodynamics, propulsion, styling, structures and manufacturing teams, each with an equal seat at the table during each step of design and development.

But perhaps the most important thing is to stay up to date on where composites manufacturing is moving and connect with the many materials, equipment and technology suppliers that want to share their expertise and help develop future applications. Reach out to us at CompositesWorld because that’s what we do — provide technical, reliable connections and information.

Related Content

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)