CAMX 2021 exhibit preview: A&P Technology

A&P Technology highlights its TX-45, which combines the mechanical performance of T1100G 71E 12k carbon fiber and offers significant cost savings.

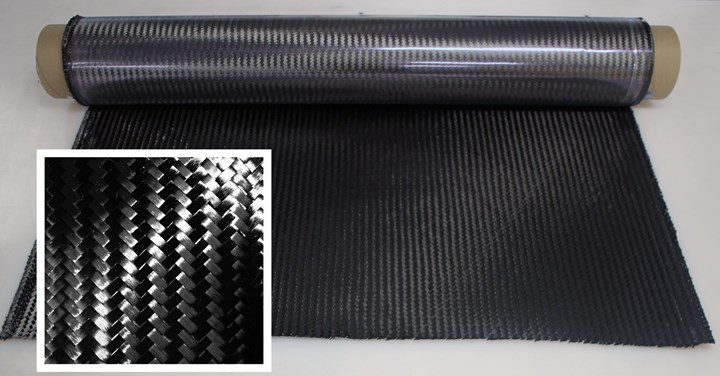

Photo Credit: A&P Technology

A&P Technology (Cincinnati, Ohio, U.S.) converts Toray Composite Materials America’s (TCMA, Tacoma, Wash., U.S.) T1100G 71E 12k carbon fiber into TX-45 — 197 GSM 45° fabric — which the company says provides performance improvements and significant cost savings.

T1100G 71E 12k carbon fiber offers a strength of 1,017 KSI and a tensile modulus of elasticity at 47 MSI. This combination of high strength and high modulus allows composite fabricators to reduce weight without sacrificing performance.

A&P Technology reports that its braiding equipment, capable of handling a range of fiber types, is able to process T1100G 71 E 12k into a lightweight, 45° fabric combining the advantages of T1100 performance with the cost savings found with off-the-roll 45° material. TX-45 is a continuous 45° fabric with uniform fiber architecture delivered on carrier film that enables easy handling and consistent fiber orientation. For parts requiring high shear strength, TX-45 reportedly eliminates the need to cut woven fabric on the bias to create 45° material, reducing labor and eliminating waste. In addition, TX-45 provides extreme drapability for highly contoured parts.

Further, A&P Technology notes that the optimized mechanical performance, cost and time savings enabled by T1100 IM+ TX-45, as well as A&P’s 0°, ±60° QISO fabric made with T1100, has attracted the attention of several aerospace customers interested in qualifying this material. TCMA and A&P Technology are pursuing development of a T1100G 71E TX-45 database to expedite qualification efforts.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.