CAMX 2020 exhibit preview: Janicki Industries

Janicki Industries is featuring its fast prototyping process for flyaway parts and tooling for urban air mobility (UAM) vehicle manufacturers.

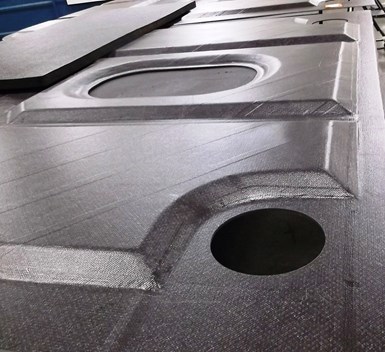

Carbon fiber production tool for aerospace parts. Source | Janicki

Janicki Industries (Sedro-Woolley, Wash., U.S.) is featuring its fast prototyping process for flyaway parts and tooling for urban air mobility (UAM) vehicle manufacturers. Specifically, the company highlights its use of large-scale, 5-axis milling to create large, precise, prototype tooling for the marine, defense and aerospace industries, and parts and tools produced for the aviation industry for more than 25 years. Within the more recent landscape of urban air mobility, Janicki says its fast prototyping process supports vehicle manufactures to test their latest concepts in real-world conditions.

Carbon fiber flyaway part for an aerospace application. Source | Janicki

The company has a dedicated 160,000-square-foot building that supports prototype fabrication, short runs and assembly of air vehicles, and its large-scale, 5-axis machining streamlines the manufacturing processes from concept to product. Janicki also mills shape foam, fiberglass, carbon fiber, aluminum, Invar and steel into complex shapes required for aerospace products.

The company says its newest parts facility is optimized for production quantities of carbon fiber parts, with more 90,000 square feet of plant space and equipped with an autoclave, core sculpting, a cleanroom, non-destructive testing equipment, furnaces, waterjet cutters and curing ovens. Janicki says it is Nadcap-certified for fly-away carbon fiber composite parts with a proven history supporting leading aerospace firms.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)