CAMX 2019 exhibit preview: Ultran Group

The Ultran Group to highlight its U710x turnkey non-contact ultrasonic inspection system at CAMX 2019.

Source | The Ultran Group

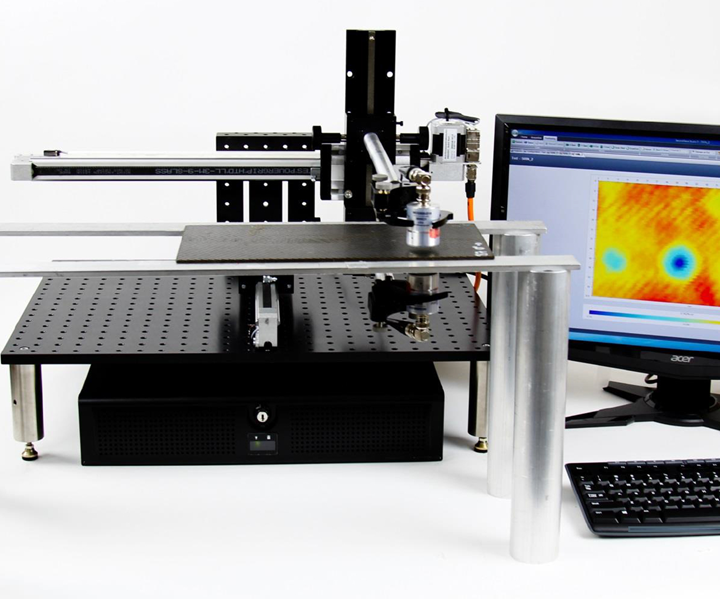

The Ultran Group (State College, Pa., U.S.) will be highlighting its U710x turnkey non-contact (air-coupled) ultrasonic inspection system at CAMX 2019.

Designed for detecting and measuring voids, cracks, porosity, density and thickness without the need for immersion or a coupling agent, the U710x provides freedom from touch and contamination of porous materials. According to the Ultran Group, it can scan parts fast and with higher signal to noise ratio than other non-contact quality inspection systems in the industry.

The system’s lightweight design is versatile and portable, facilitating its use in a wide variety of applications.

Related Content

-

What to expect at CAMX 2022

The Composites and Advanced Materials Expo (CAMX), the largest composites industry trade event in North America, takes place Oct. 17-20, 2022 in Anaheim, Calif., U.S.

-

CAMX 2022 exhibit preview compilation, Part 1

CompositesWorld presents some of the 120 exhibitor previews received highlighting key technologies, services and trends at this year’s CAMX.

-

Elastomer reusable vacuum bags address traditional material limitations

CAMX 2023: Sprayomer Technology Amor-Vac RVBs, distributed by Technology Marketing, are said to be more efficient, sustainable, long-living and lighter in weight compared to sprayable silicone or nylon film alternatives.

.png;width=70;height=70;mode=crop)