CAMX 2019 exhibit preview: Goodwinds Composites

Goodwinds Composites will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019.

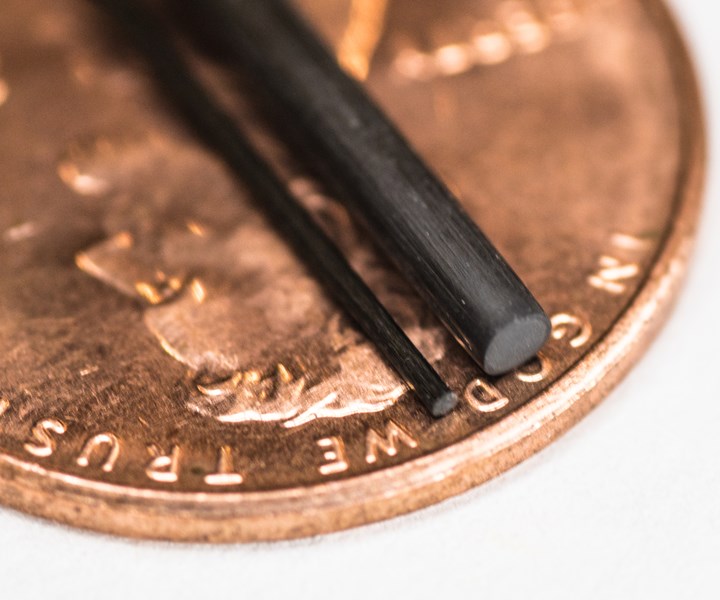

Micro-pultruded carbon rods

Source | Goodwinds Composites

Goodwinds Composites (Mount Vernon, Wash., U.S.) will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019 (Booth Z46), September 23-26, in Anaheim, Calif.

The micro-pultruded carbon rods are produced in short runs and can have a diameter as small as .020 inches. Frequently used for z-axis reinforcement of laminate stacks, Goodwinds Composites’ micro carbon has all the attributes of larger pultruded carbon rods such as excellent stiffness-to-weight ratio and high Fiber volume Fraction. Additionally, tooling costs for custom micro-pultruded rods are relatively low.

Goodwinds Composites’ wrapped carbon tubes can be found in guitars, tents, backpacks, hiking poles, pool cues and the NASA Mars Helicopter. Goodwinds Composites is well-versed in metrology and can precisely and repeatedly machine composite rods and tubes to tight tolerances. The company’s capabilities include notching, milling, drilling, sanding, cutting and grinding to specific outer diameters.

Related Content

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

.png;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)