VABO Composites to build superstructure, mast for Royal Van Lent yacht

Lightweight marine composites production to be further advanced using robotic automation.

VABO Composites has an exciting contract with the Dutch high-end yacht builder Royal Van Lent to build a more than 800-m2 composite superstructure and mast. Composites, chosen for the topside of this yacht to save weight, will include both glass and carbon fiber as well as resin infusion processing. VABO Composites will be responsible for the concept-engineering, calculations, mold design, mold fabrication and construction of all elements, which will be delivered ready for installation and final painting.

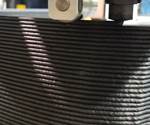

As part of this 12- to 18-month project, VABO Composites will use its new robot on a track for both mold and parts fabrication, with possible thermoplastic 3D printing for some parts of the mold. “We are very proud of this contract with Royal Van Lent and excited to take the next step in our composites production, using robotics on this unique and challenging project,” said VABO Composites president Arnold Vaandrager. “The engineering has already started, and we will keep the industry updated on our progress.”

For more details on VABO Composites and the use of composites in marine superstructures and masts, see “Composite radar masts assembled for megayachts” and “VABO Composites: Dutch innovator excels in diverse applications”.

Related Content

-

Airborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

-

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

.jpg;maxWidth=300;quality=90)