Solvay showcases low-cost prepreg and parts approach using Cygnet Texkimp filament winder

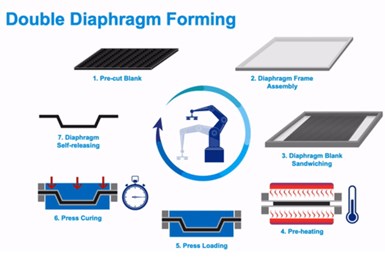

High-speed, tailored preforms are used with Solvay double diaphragm forming (DDF) and compression molding to produce cost-effective, medium-volume auto and aero parts.

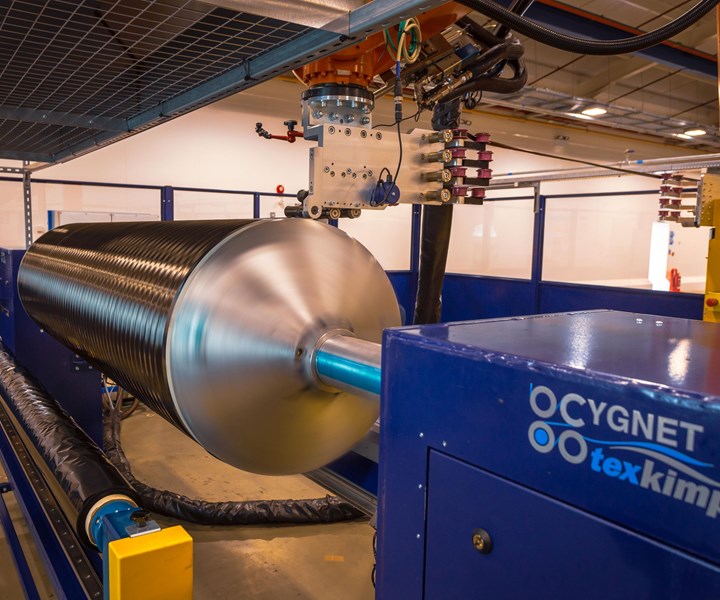

Composite materials and technology supplier Solvay (Alpharetta, Ga., U.S.) has installed a four-axis robotic filament winding machine designed and built by fiber handling specialist and custom machinery manufacturer Cygnet Texkimp (Cheshire, U.K.) to make low-cost prepreg material and composite parts.

The bespoke winding machine was installed at Solvay’s U.K. Application Centre, an R&D facility based in Heanor, where the company develops new technologies and processes for the adoption of composites in high volume markets including automotive and aerospace.

High-speed, multi-layer preforms

SOURCE | Solvay

The filament winder was designed by Cygnet Texkimp to enable production of large composite material sheets, or preforms, which can be molded using Solvay’s double diaphragm forming (DDF) technology and compression molding. The goal is to create cost-effective exterior parts for the automotive industry, including hoods and trunk lids.

“The machine we developed is, in effect, a semi-automated drum winder,” explains Cygnet Texkimp managing director Luke Vardy. “But unlike traditional machines of this kind, it is capable of winding fiber in a much wider range of angles, providing customers with greater flexibility in tailoring material properties within multi-layer preforms.”

The winder is capable of winding at a fiber speed of up to 100 meters/minute and has been built to accommodate a mandrel spanning 2.2 meters in length by 0.6 meters in diameter, to produce preforms sized up to 2 square meters. The finished wind is sliced from the mandrel and trimmed to size using an integrated, automatic cutting unit before being transported to the next stage of processing on a dedicated transfer table.

“Cygnet Texkimp worked closely with us to develop a highly controlled and efficient process that removes a lot of the labor requirement and allows us to show our customers how they can produce carbon fiber prepreg quickly, cost-effectively and competitively using our resins and materials,” said Richard Russell, Process Engineer at Solvay. “For the automotive market in particular, this is a very interesting alternative way to make high-performance composite parts in medium volumes.”

Constant tension for spread tow

The winder takes dry fibers, or tows, from an integrated, four-position driven creel, and feeds them onto an application head. The driven creel controls fiber tension throughout the process. This ensures consistent spreading despite variations in fiber speed which occur throughout the winding process.

Solvay has demonstrated double diaphragm forming using a filament-wound tailored preform, hot compression molding and matched metal tools for a BMW M4 GTS hood. Source | Solvay

The four tows are spread over the application head to create a 50-millimeter wide consolidated sheet or tape onto which Solvay’s resin system is applied, immediately before it is laid onto the mandrel.

Cygnet Texkimp’s design incorporates a resin metering system to mix Solvay’s advanced resins at the point of application, and in doing so eliminates the issue of pre-mixed resin curing before application or needing to be stored under special conditions.

Solvay has also worked with BMW (Munich, Germany) to demonstrate production of an M4 GTS hood using diaphragm forming of filament wound carbon fiber preforms.

For more details, see Solvay’s “Composites Materials for Automotive Applications” brochure (p. 7).

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More