Six candidates nominated for "Biocomposite of the Year 2019"

Natural fiber composites and wood plastic composites compete for 7th annual innovation award.

Today, up to 80% of plastics can be replaced by bio-based fillers such as wood flour and cork or reinforced by natural fibers. These biocomposites are available for almost every application — including packaging, consumer goods, building façades and interior components, and automotive parts — as demonstrated by this year’s nominated companies.

The winners of the innovation award “Biocomposite of the Year 2019” will be chosen at the 8th Biocomposites Conference Cologne (Nov 14-15, Cologne, Germany), where exciting new biocomposite technologies and applications will be discussed via a broad range of topics. The day before and parallel to the conference, EU project-related workshops will feature international biocomposites experts presenting and discussing case studies, market figures and strategies for a circular wood value chain.

Out of 15 applications for this year’s biocomposites innovation award, six new materials and products have been nominated for the innovation award by the conference advisory board. Each finalist will give a 10-minute presentation at the conference, after which, three winners will be elected by the conference participants. Each of the six finalists below offers significant potential to help address global issues with waste, CO2 emissions and the future of our planet’s irreplaceable natural resources.

Car door using PowerRibs. SOURCE | Bcomp

PowerRibs – sustainable lightweighting

Bcomp (Fribourg, Switzerland) has developed proprietary light-weighting solutions for high performance applications by combing the latest composites knowledge with natural fibers. PowerRibs uses a reinforcing grid. inspired by the thin veins in leaves, to provide maximum stiffness at minimum weight. This enables natural fibers to achieve the performance of carbon fibers in a motorsport body, for example, resulting in a 75% lower CO2 footprint, 30% lower cost and improved safety without toxic dust and shattering upon impact. PowerRibs are also used to make automotive interior panels up to 40% lighter, and offer more sustainable options for end-of-life structures.

SOURCE | Lingrove

Ekoa veneers – sustainable composites to replace wood

Lingrove (San Francisco, Calif., U.S.) produces high-performance biobased composites, including the Ekoa and Ekoa TP product lines using flax fibers and biobased thermoset and thermoplastic resins, respectively. Lingrove’s biodegradable Ekoa veneers offer a higher stiffness/weight ratio vs. steel, lighter weight vs. carbon fiber and have the look and performance of old-growth wood. For example, Blackbird guitars made with Ekoa look like wood, but resist effects from humidity and sunlight better than wood, while preventing deforestation of non-replaceable old-growth/rain forests. In sporting goods, Ekoa provides a unique aesthetic and dampens vibration. Lingrove is currently scaling veneer and panel production to meet demand from automotive, furniture and interiors applications.

OrganoComp and molding of large, 3D biocomposites

OrganoClick (Täby, Sweden) launched its OrganoComp biocomposite in May 2019. A patented, 100% biobased material made from Swedish wood fiber and a biopolymer binder produced from food and pulp industry byproducts such as orange peels and shrimp shells. OrganoComp is produced with a patented production technology for molding large, 3D-shaped biocomposite components and is replacing hard plastics, MDF-boards and particle boards that contain synthetic glues used in applications like interiors, furniture, acoustic panels, waste containers and burial coffins. The strength of OrganoComp enables 50% raw material reduction of a coffin, for example, while maintaining a traditional appearance.

SOURCE | Dometic and Trifilon

Market-tested biocomposites made with hemp fibers

Trifilon (Nyköping, Sweden) offers a green alternative to plastics with its BioLite material: polypropylene with up to 30% hemp fiber reinforcement. Hemp is one of the strongest natural fibers in the world, making BioLite products strong, light and durable. BioLite is supplied as granulates for injection molding. Trifilon also produces BioForm for compression molding. Applications include vehicle components, luggage, coolers, consumer goods, packaging and containers. BioLite achieves a 26% lower carbon footprint compared to conventional polypropylene in PhantomBIO luggage and Dometic’s Coolfun SC30B cooler housing .

Source | KNN Cellulose

Recell biocomposite – the cost-competitive alternative

Recell Group (Leeuwarden, Netherlands) has commercialized Recell biocomposite, a granulate biocomposite made using cellulose from recovered toilet paper and biopolymers such as PLA or PHA. The resulting product is fully biobased, compostable and competitively priced with low environmental impact. The granulate is suitable for standard injection molding and extrusion processes. Current applications include fencing, decking, crates and building cladding. Featured in this year’s competition is a picnic table produced by EcoDeck using Recell cellulose fibres efficiently produced from Sewage Treatment Plants (STPs) with Cellvation technology. This benefits STPs with lower operational costs and increased processing capacity while the fibers are reused instead of being incinerated.

Home compostable coffee capsules

Golden Compound (Ladbergen, Germany) has introduced HOMEcap, the world’s first and only home-compostable coffee machine capsule, which uses fleece made from ground sunflower seed fibers as a reinforcing material. This material, dubbed “Golden Compound green”, has unique characteristics: the oxygen barrier is very much comparable with conventional plastics, is aroma-proof and avoids exterior packaging. Home composting such commonly used (and discarded) items as coffee capsules significantly reduces waste streams. A VDI 4605 sustainability assessment showed that HOMEcap outperforms current state-of-the-art capsules, such as those made with multi layers of deep-drawn PP EVOH, in terms of sustainability.

Related Content

Lingrove plant-based ekoa composite featured in Hyundai Palisade concept vehicle

Carbon-neutral biocomposite enables interactive doorspear with look and feel of wood while protecting trees, enabling transparency and capacitive touch for futuretech.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePorcher Industries launches new range of flax fiber-based thermoplastic composites for automotive

Composite stiffeners, sold as textiles, are made primarily of flax fibers grown, selected, mixed and woven in France for modern, durable and environmentally conscious applications.

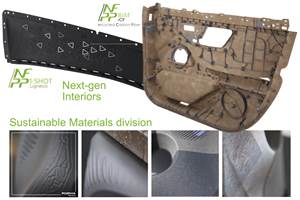

Read MoreFaurecia advances biocomposites, recyclability, reduced CO2 and sustainability in automotive

Efforts include advancing NAFILean materials family in weight reduction and sustainability, as well as new Sustainable Materials division and R&D Center.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More