SGL, Fraunhofer launch fiber placement tech center

The Fiber Placement Center in SGL’s Meitingen, Germany, facility is also supported by Compositence GmbH and BA Composites GmbH.

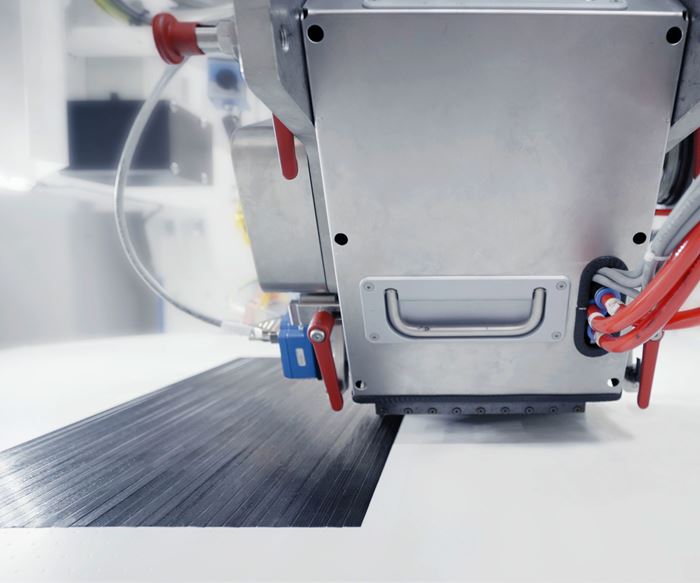

SGL Group (Wiesbaden, Germany) and Fraunhofer IGCV announced on Feb. 12 that they have founded a joint Fiber Placement Center headquartered at SGL’s facility in Meitingen, Germany. System manufacturers Compositence GmbH and BA Composites GmbH have also joined the cooperative effort.

With more than 500-m2 of lab space, the center offers customers the opportunity to develop production concepts and demonstrate their feasibility by prototyping. Furthermore, in the event of a demonstrated cost benefit, SGL Group may implement an industrial production of fiber-reinforced parts. Both dry and pre-impregnated fibers with or without thermoplastic matrix systems will be processed. This work, says SGL, is synergetic to the ongoing R&D activities performed by SGL’s Lightweight and Application Center in Meitingen, the research team from Fraunhofer IGCV in Augsburg and the chair for Carbon Composites at the Technical University of Munich.

Bilateral projects with aerospace companies for secondary and primary structural parts in various aircraft types are already prepared at the Fiber Placement Center, along with development projects in collaboration with various automotive parts manufacturers worldwide.

“Fiber placement enables a high degree of automation in production, while offering high flexibility and extremely efficient material utilization. These technologies, which are already established for aerospace applications, will be transferred into other industrial sectors for highly efficient large-scale production. For many of our customers, this is a promising opportunity to exceed existing process capabilities for serial production of components made from fiber-reinforced plastic,” explains Andreas Wüllner, head of the Composites – Fibers & Materials Business Unit at SGL Group.

“The Fiber Placement Center clearly reflects the mission of the Fraunhofer Society, to provide substantial support in knowledge transfer to the industry by means of applied research and to advance the industrialization of fiber-reinforced plastics. Fiber placement processes are well suited for future applications due to their high level of automation and material efficiency. These developments benefit significantly from industry-oriented research activities,” adds Dr. Klaus Drechsler, head of chair of carbon composites at the Technical University of Munich.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.