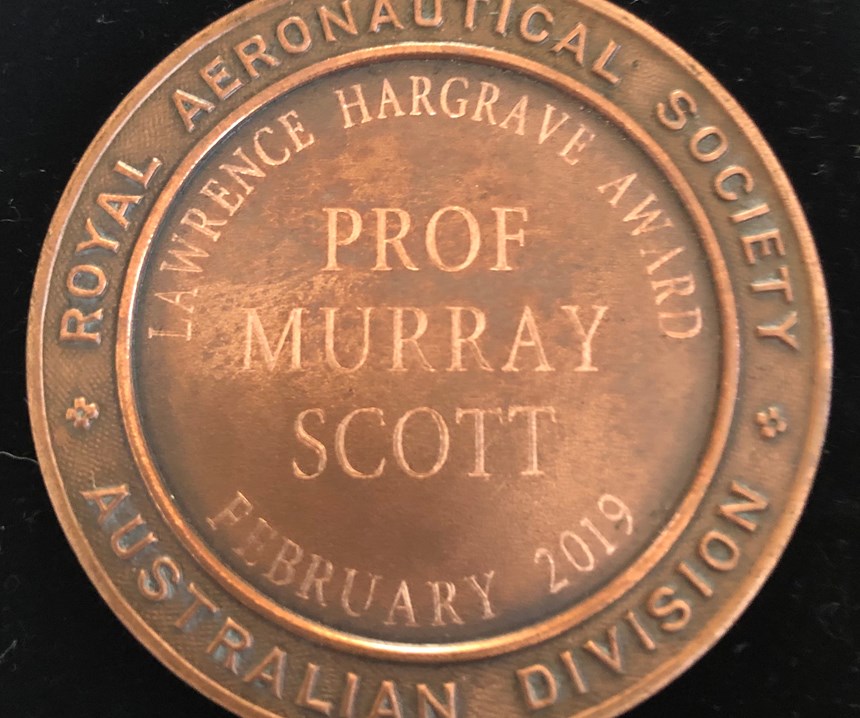

Royal Aeronautical Society awards 2019 Lawrence Hargrave Award to Murray Scott

The Royal Aeronautical Society Australian Division has announced Professor Murray Leslie Scott as the 2019 winner of the biennial Lawrence Hargrave Award.

The Royal Aeronautical Society Australian Division has announced Professor Murray Leslie Scott as the 2019 winner of the biennial Lawrence Hargrave Award for an Australian who has made a significant contribution to Australian aviation. The award was presented by Noel Schmidt, AM CSC FRAeS, the Australian Division past president air vice marshal, at the 18th Australian International Aerospace Congress (AIAC) Dinner on February 25 in Melbourne.

Scott, BEng (Aero), MSc (Aircraft Design), FTSE, FRAeS, FAICD, FAIM, FIEAust, CPEng, has over 35 years’ experience in the field of aerospace engineering. He has made an outstanding contribution to the design and manufacturing of advanced fiber-composite aerospace structures, primarily as CEO of the Cooperative Research Centre [CRC] for Advanced Composite Structures. This CRC underpinned the design and production of advanced composite structures for the Boeing 787 wings — a notable highlight for Australia’s aerospace manufacturing capability. He has also played pivotal leadership roles in establishing other high-value R&D programs such as CRCACS Helicopter Composite Structures (2007); Defence Materials Technology Centre (2008); CRC-ACS Extension Program (2010); and Innovative Manufacturing CRC (2015). In 1992, Scott founded the Australian Composite Structures Society, a Technical Society of Engineers Australia, which has been instrumental in fostering expertise in advanced composites in Australia. He co-edited the book “Composite Materials for Aircraft Structures,” now in its third edition, which is still the only book on such an important topic and represents a “Team Australia” effort. He has also brought a considerable international focus to Australia’s capabilities in aeronautics and composites through attracting major international conferences to the southern hemisphere, several for the first time. He was also a co-founder of the AIAC congress series which started in 1985 and chaired the Congress in 2005. This major event has now reached the 18th in the series with AIAC18 held February 24-28, 2019, in Melbourne aligned with the biennial Australian International Air Show at Avalon.

Due to his many company and academic appointments, Scott has been elected honorary fellow of the International Council of the Aeronautical Sciences (ICAS) and also served a two-year term as president, and is also a world fellow of the International Committee on Composite Materials (ICCM) and has served a term as president. He also has been for many years chairman of the EA / RAeS Joint Board for Aerospace Engineering.

The Australian Division of the Royal Aeronautical Society established the Lawrence

Hargrave Award 20 years ago to recognize achievement at all levels and in all disciplines

of aerospace within Australia. The Lawrence Hargrave Award honors one of Australia’s

true pioneers of flight. Hargrave’s experiments with box kites at Stanwell Park near

Sydney in the 1890s proved to be one of the most significant early developments in

aviation.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

.jpg;width=70;height=70;mode=crop)