Orbital ATK's place in space

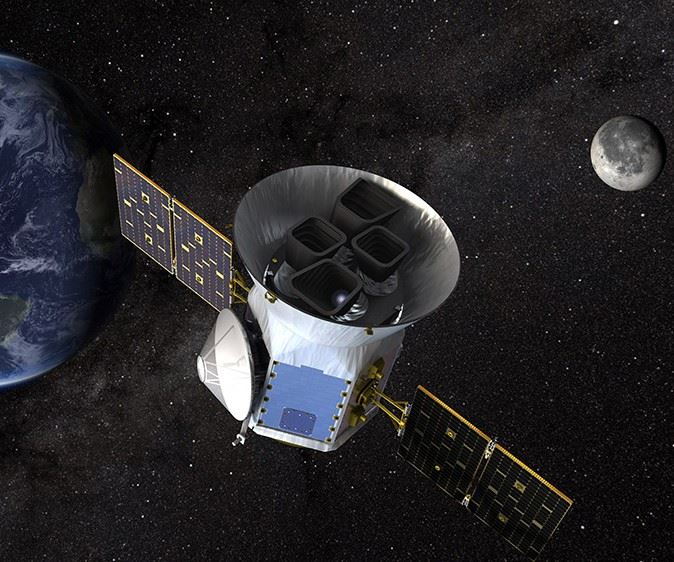

TESS exoplanet survey satellite and United Launch Alliance Atlas V launches mark recent successes for aerospace technology leader Orbital ATK.

Orbital ATK (Dulles, VA, US) has some reasons to celebrate. The global leader in aerospace technologies recently saw the successful launch of its Transiting Exoplanet Survey Satellite (TESS), which the company built for NASA, as well as critical contributions on three recent three United Launch Alliance (ULA) Atlas V vehicles.

TESS Satellite to search for nearby extra-solar planets on multi-year mission

TESS was launched on April 18 aboard a SpaceX Falcon 9 rocket. As the first-ever exoplanet satellite to perform a survey of the entire sky, TESS will identify planets ranging from Earth-sized to Jupiter-sized, orbiting a wide range of stellar types and in various orbital regimes. The principal goal of the TESS mission is to use four wide-field cameras to detect small planets around bright host stars in the solar neighborhood so that detailed characterizations of the planets and their atmospheres can be performed.

Liftoff occurred at 6:51 p.m. EDT from Cape Canaveral Air Force Station, FL, US. The satellite separated successfully from the launch vehicle 49 minutes into the mission. Orbital ATK completed the satellite’s post-launch health checks and configuration activities in preparation for a series of in-space maneuvers, including a lunar gravitational assist, to reach its targeted highly-elliptical orbit. Once in-orbit testing has been completed, TESS will begin its initial two-year mission approximately 60 days after launch.

“The data from our first tests show TESS is in good health and performing as expected early in its mission,” says Steve Krein, vice president of Science and Environmental Satellite Programs at Orbital ATK. “TESS adds to our growing list of successful scientific space missions that have helped us study the Earth and Sun, explore the solar system, and probe the mysteries of the universe. This successful launch marks the 31st science spacecraft we have developed and built for NASA over the last 35 years, and continues to demonstrate Orbital ATK’s expertise in delivering the high-quality satellites our customers expect.”

Orbital ATK has a rich history of designing and manufacturing small space science satellites. From a small, low-cost astrophysics mission like GALEX, used to explore the origin and evolution of galaxies and stars, to Earth-imaging satellites such as the Landsat series, which have been monitoring surface changes for over 45 years, to the Dawn spacecraft, the first deep-space mission to orbit two interplanetary bodies in the main asteroid belt between Mars and Jupiter, the company’s robust spacecraft platforms and comprehensive engineering know-how have enabled many of these satellites to far exceed their design lifetimes.

TESS was built at Orbital ATK’s Satellite Manufacturing Facility in Dulles, VA, US and is based on the company’s LEOStar-2 bus, a flight-proven and flexible satellite platform that accommodates a wide variety of missions. Continuing the company’s legacy for delivering high-performance science and environmental spacecraft, several similar satellites are now in production for upcoming NASA missions that include the ICON heliophysics explorer, also built on a LEOStar-2 platform, as well as the Earth science ICESAT-2 and Landsat-9 satellites and the JPSS-2 weather spacecraft which use the larger LEOStar-3 bus.

TESS is a NASA Astrophysics Explorer mission led and operated by the Massachusetts Institute of Technology and managed by the NASA Goddard Spaceflight Center. More than a dozen universities, research institutes and observatories worldwide are participants in the mission.

Contributions from Orbital ATK have played a critical role on every EELV launch

Orbital ATK recently supported the launches of three United Launch Alliance (ULA) Atlas V vehicles with critical components and technologies from multiple divisions across the country. Orbital ATK has played a critical role on every Evolved Expendable Launch Vehicle (EELV) launch since the Air Force program began in the late 1990s. All three launches took place within 12 weeks and included multiple launch vehicle and payload hardware components manufactured by Orbital ATK.

“Orbital ATK is proud to contribute multiple key technologies from across the company to both the ULA launch vehicles and their satellite payloads,” says Steve Earl, vice president and general manager of Orbital ATK’s Aerospace Structures Division. “For these three successful launches in just 12 weeks, our collective products play an important role in ensuring missile warning and missile defense, more accurate and reliable weather forecasts and valuable scientific knowledge from experiments performed in space.”

For all three launches, Orbital ATK produced the ULA Atlas V vehicles’ 10-foot diameter composite heat shields, which provide essential protection for each first stage. For the GOES-S and AFSPC-11 launches on March 1 and April 14, respectively, Orbital ATK provided two additional composite structures on each of ULA’s Atlas V launch vehicles, which include the Centaur Interstage Adapter (CISA) that houses the second stage engine, and the boattail that adapts from the core vehicle to the five-meter diameter fairing. Orbital ATK fabricated all of these large composite structures at the company’s facility in Iuka, MS, US.

Orbital ATK also manufactured the ULA Atlas V rockets’ Reaction Control System propellant tanks at its Commerce, CA, US facility. In addition, eight solid motors supported the separation of each rocket’s spent first stage. The company built the retrorockets at its facility in Elkton, MD, US.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.png;width=70;height=70;mode=crop)