NIAR begins construction on new ATL, AFP lab

The Advanced Laboratory for Aerospace System (ATLAS) will develop manufacturing protocols for automated fiber placement (AFP) and automated tape laying (ATL) for aircraft systems.

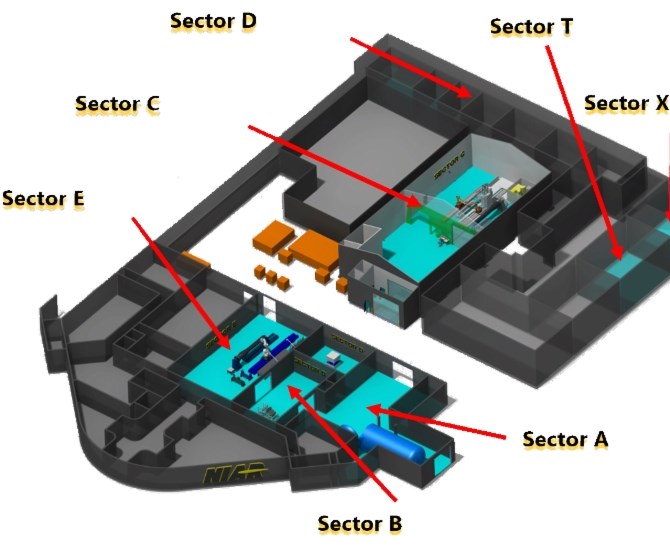

The National Institute for Aviation Research (NIAR) at Wichita State University (Wichita, Kan., U.S.) has begun construction on its new Advanced Laboratory for Aerospace Systems (ATLAS), which is located on the main campus headquarters and is expected to be completed in the summer of 2020.

ATLAS will be a facility for the development of manufacturing protocols for automated fiber placement (AFP) and automated tape laying (ATL) for aircraft systems incorporating real-time inspections and machine learning algorithms. NIAR senior research scientist Waruna Seneviratne will lead the lab.

Equipment and personnel within ATLAS will specialize in various areas: digital twin manufacturing technology development, rapid prototyping and manufacturing, machine learning, “Factory of the Future,” and cybersecurity and sabotage protection.

Two of the sectors for the lab are complete, two more are expected to be completed in the fall, with the rest expected to be completed in the summer 2020.

“ATLAS provides a neutral ground for manufacturers to research advanced manufacturing concepts with various machine, software and processing options,” says Seneviratne. “It will also educate and train student Factory of the Future engineers on advanced manufacturing concepts.”

NIAR also recently was awarded a $2 million grant to go toward research equipment for the ATLAS facility.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

.jpg;width=70;height=70;mode=crop)