Molding in fasteners to CFRP parts

Placed into the mold prior to RTM, compression or injection molding/overmolding, this specially-shaped fastener enables composites to be fastened with standard methods used for metal parts.

The goal was a fastener strong enough to fasten a composite part, but also be cost-competitive and amenable to high-volume production. “Attachment to metal floors can be easily industrialized using fully robotic processes,” says Bernard. “So the idea for IMTEC HR was an industrialized solution for composites with no manual operations.” IMTEC HR fasteners can be placed into the mold for a composite floor structure and integrated during the molding process. Bernard cites IMTEC HR as compatible with thermoset and thermoplastic molding processes, including resin transfer molding (RTM), compression molding and injection molding/overmolding.

For injection molding, the fastener is robotically placed first onto a pin fixed on the mold. The pin locates the fastener and protects the threads inside of it from being coated with resin. Next, the composite material is robotically placed into the mold. The mold is closed, the plastic injected and the part demolded with fastener integrated.

For compression molding, the process is essentially the same except the pin is a plastic screw-off “cap” and also serves to push the material aside for inserting the fastener into the composite, thereby eliminating the need for hole drilling. This not only saves time, it avoids cutting the fibers. The pin cap again protects interior threads during molding and is removed after the part is demolded.

“There are no extra operations once the floor is produced,” notes Bernard. “We believe this technology helps to make composite floors or any other structural parts with an affordable production cost. It replicates the used of blind rivets with metal floors because the fastener is already there in the molded composite part. You now attach the seat with standard methods. This equals the playing field because parts can be attached to a composite floor the same as to a metal floor.”

SOURCE: Böllhoff

To resist galvanic corrosion, IMTEC HR is available in zinc-plated steel and in stainless steel, the latter used mainly for carbon fiber reinforced plastic (CFRP). Different fastener versions are also available, including bolts (studs), nuts and spacers. “We can also change the size of the holes and dimensions of the fastener to meet specific requirements,” says Bernard.

Special shape for energy absorption

I asked Bernard about the shape of these fasteners, explaining they looked similar to others I had seen, including Big Head and Spida Fixings. He said the shape is reminiscent but different, developed to allow the gradual release of energy during crash conditions. “It is strong enough to provide a high mechanical performance but can absorb energy in crash test conditions to avoid catastrophic brittle failure,” he explains. “It enables elastic then plastic deformation without breaking. Without this behavior, the composite floor at the attachment would deform and break or the metallic fastener would break. This was one issue with adapting fasteners for composite structures.”

|

|

Big Head (left) and Spida Fixings (right) fasteners for composites.

SOURCE: Big Head and Spida Fixings.

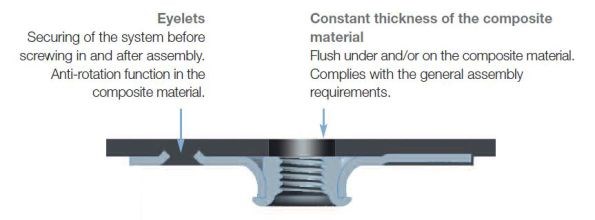

Another aspect of the shape is the petals. “These are designed to embed in the composite material during molding,” says Bernard. “You must design this fastener to embed in the part and not be left in the mold.” He also notes that the fastener flange is behind the composite part and does not reduce the part section thickness. “This is important to achieve an embedded fastener while maintaining the part section, which gives structural properties.”

Böllhoff’s IMTEC HR fastener developed for molding process embeds into the composite part without reducing section thickness. SOURCE: Böllhoff.

A special version of IMTEC® HR has been developed with Cetim which is compatible with the QSP production line. Cetim is the French research organization that has developed the Quilted Stratum Process (QSP) for highly automated production of composite parts.

According to an article published by Cetim, the patent pending IMTEC HR fastener developed for QSP shows a 30-75% increase in pull-through performance and 60-75% improvement in lap-shear performance compared to conventional fasteners.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreRead Next

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More