Mikrosam to supply GKN Fokker with AFP, consolidation equipment for thermoplastic composites

The suite of equipment includes Mikrosam’s latest automated fiber placement (AFP) machine, slitting equipment for thermoplastic prepregs and a custom-engineered thermoplastic consolidating machine.

Source | Mikrosam

Mikrosam (Prilep, Macedonia) announced on Dec. 3 that it will deliver advanced equipment to GKN Fokker (Redditch, U.K.) for development of thermoplastic composite (TPC) aircraft parts. The suite of equipment includes Mikrosam’s latest automated fiber placement (AFP) machine, slitting equipment for thermoplastic prepregs and a custom-engineered thermoplastic consolidating machine. When installed, the company says this equipment will add to GKN Fokker’s advanced manufacturing and R&D capabilities to produce complex 3D parts for the aviation industry.

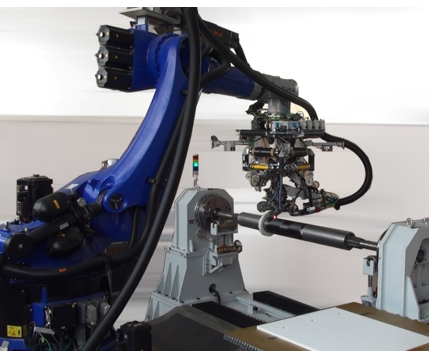

Mikrosam says its AFP solutions for thermoplastic composites are cost-competitive and proven, with many advancements for maximum productivity. Designed as an integrated, modular and upgradeable AFP work-cell, the 8-axis robotic AFP machine is reportedly capable of automated and precise placement of thermoplastic fibers.

The system uses a multi-material AFP head with bi-directional placement on open and closed 3D shapes and mandrel surfaces. Combined with an automatic head exchange system, customers can obtain new multi-tow AFP or automated tape laying (ATL) heads, or additional equipment for future use on the same work cell. Mikrosam’s AFP heads are also designed with flexibility and time-saving features, such as easy access to material spools, and quick servicing of consumable and spare parts with minimized downtimes to ensure high reliability, productivity and flexibility in advanced composites manufacturing. Using a laser heating source, precise temperature and angle control, and a closed-loop process, Mikrosam’s AFP machines are reported to have proven results for in-situ consolidation of TPCs with better mechanical properties.

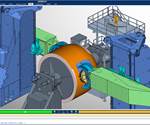

In addition to the AFP system, GKN Fokker will receive equipment for wide and narrow prepreg tape slitting and rewinding to prepare spools. According to Mikrosam, the slitting and rewinding machine works with thermoplastic prepregs to produce spools of various sizes and re-winding styles, ranging from 300-millimeter-wide tape to ¼-inch-wide tapes. Additionally, Mikrosam will deliver a custom-engineered consolidation press for advanced products made of thermoplastic composites. The complete automation of the AFP machine is powered by MikroPlace, a CATIA-compatible solution for analysis and simulation of composite parts, as well as QCS (Quality Control System), which offers continuous improvement via data monitoring and traceability. Read more about this and other recent advances in AFP/ATL software.

“Today, the market demands better automated thermoplastics layup and higher utilization of AFP machines. Our modular, upgradeable AFP systems give customers higher ROI with the ability to use multiple AFP or ATL heads on the same configuration. Customers can reduce cycle-times for parts and increase utilization of the AFP work cell. When combined with our sophisticated control for in-situ consolidation of thermoplastic composites, our AFP machines provide excellent solutions for many industries,” says Dimitar Bogdanoski, sales manager at Mikrosam DOO.

“We are pleased by Mikrosam’s professionalism and innovative drive, as well as the quality of the machines,” says Arnt Offringa, thermoplastic composites technology manager at GKN Aerospace.

Read more about the evolving role of thermoplastic materials and processes, and their future in next-generation commercial aircraft.

Related Content

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

.jpg;width=70;height=70;mode=crop)