Mikrosam delivers automated filament winding line to Magna

Integrated production cell for high-volume production of composite CNG tanks installed in Graz, Austria plant.

Composite manufacturing equipment supplier Mikrosam (Prilep, Macedonia) has delivered a fully automated filament winding line for CNG tanks to leading global automotive supplier Magna and installed the system in its Graz, Austria plant. This production cell was developed for manufacturing cost-effective, lightweight CNG tanks using composite materials, which could reduce vehicle weight by up to 50% and fuel expenses by up to 40%.

Mikrosam’s fully integrated composite manufacturing solution comprises:

- Multi-spindle filament winding machines with the company’s patented automated cut & restart of the fibers/tape during winding process;

- Automatic handling of liners and wound and cured tanks between numerous equipment units in the production process;

- Sophisticated curing oven that accommodates the requirements of different resin systems.

The winding machine is equipped with two winding carriages — one for winding the main composite structure and one for winding of the outer protective layer — enabling full continuous production of CNG tanks on the same machine in a single winding cycle. A total of 24 servomotor-controlled axes are integrated into the filament winding machine itself, which makes it one of the most advanced winding machines in the world.

This production line is also unique in its flexibility to change production from one tank size to another, with all programs — mechanical and electrical parts — automatically adjusted to the new CNG tank size. The ability to make these changes and adjust the capacity of each equipment station quickly increases productivity of the overall production line.

Control and monitoring of the work cell and overall manufacturing process is carried out from one place, the top level automation control system (TCON). It manages all modules in the integrated production line from one location while recording raw material consumption, complete production parameters, product tracking at every station and data for multiple quality check points.

In order to maintain high quality of the overall manufacturing process, Mikrosam develops control software and data acquisition systems that enable customer to see the line in operation, investigate it and discuss any issues before accepting final installation. After the production cell is installed in the customer facility, continued support via remote maintenance system is guaranteed. Software is updated for the lifetime of the automated production line.

Designed to fit the required high volume production capacities currently demanded, Mikrosam automated filament winding production cells optimize production rate by avoiding bottle necks; reduce material waste, increase energy efficiency and real-time control of quality at every point in the production cycle. Monitoring of the complete manufacturing process and integration of safety functions in all modes of operation are combined with flexibility in each equipment station. All of this is achieved in one package with full support, training and assistance from engineering experts.

Europe is the largest market for natural gas vehicles. With demand continuing to increase here and around the world, Mikrosam has used its 26 years of experience to develop the most advanced fully-automated, high-volume production line for filament-wound CNG, LPG and hydrogen tanks, as well as filament winding machines with up to 6-axes for complex parts; AFP/ATL machines; prepreg making and slitting equipment, and software products. Mikrosam has provided solutions to customers from more than 40 countries around the globe, including the European Union, Japan, China, Russia and India, enabling them to exceed their production objectives. For more information, visit Mikrosam at the CAMX 2016, Booth G 97.

Related Content

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

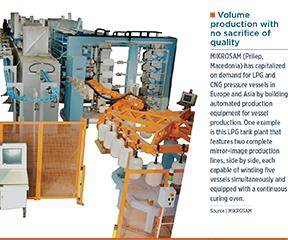

Automated filament winding enables competitive composite cylinders

Carefully controlled, robust, volume processes offer fabricators of Class IV LPG/CNG tanks a means to meet increasing demand in Europe and Asia.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)