LANXESS thermoplastic composites used in Audi A8 rear seat shell

LANXESS rear seat shell showcases the company’s continuous-fiber-reinforced composites role in large-scale production of structural components for automotive.

LANXESS (Cologne, Germany) has announced that its Tepex continuous-fiber-reinforced composites are used in a rear seat application for the Audi A8. The sedan car has an option with two electrically adjustable individual rear seats, the shells of which have been developed by Faurecia Automotive Seating (Stadthagen, Germany) and are manufactured using a hybrid molding process. Polyamide-6-based Tepex dynalite 102-RG600(2)/47% is used for this purpose. Short-glass-fiber- reinforced Durethan BKV30H2.0 polyamide 6, also from LANXESS, is used as an over-molded material.

LANXESS cites the application as an example of how its Tepex continuous-fiber-reinforced composites are becoming established in large-scale production of various structural components for lightweight automotive design.

“The reason that our composite material was chosen for this structure was the fact that it is around 45% lighter than a comparable metal design but can also be produced cost-effectively, thanks to the high degree of functional integration. It can also withstand the high mechanical loads in a crash,” explains Henrik Plaggenborg, head of Tepex Automotive at the LANXESS High Performance Materials (HPM) business unit.

Up to now, comparable seats have mainly been made using metal shells screwed onto a substructure. Manufacturing the metal shells is time-consuming as they consist of numerous individual parts that have to be joined together by means of welding in several steps.

“In the hybrid molding process, by contrast, a ready-to-install component is created in a single process step. The pre-contoured and heated semi-finished composite product is formed directly in the injection molding tool for this purpose, and equipped with numerous functions by means of injection molding. This simplifies subsequent assembly and leads to considerable savings in production costs,” says Tilmann Sontag, project manager at the Tepex Automotive group of HPM.

In addition to reinforced ribs, the piping groove for securing the seat cover in place as well as numerous holders and guides (e.g. for seat ventilation and cable holders) are integrated into the component. The clips to attach the seat shell are also directly injected.

“The shell can be assembled easily and quickly without screws using the clips, and disassembled again for servicing purposes. The clips are highly stable and meet all relevant safety requirements,” says Sontag.

LANXESS provided the project partners with comprehensive support in the development of the seat shells and the complete rear seat system. For example, HPM determined material data about the composite and over-molded material that Faurecia required for structural simulations in order to calculate the mechanical resilience of the safety component. In addition, several strategies for forming the semi-finished composite product precisely and reproducibly were analyzed in a draping simulation. The findings were incorporated into recommendations for designing the tools and processes.

“For example, we recommended special clamping elements to secure the plasticized composite insert in the injection molding tool,” says Sontag.

Tepex is developed and produced by LANXESS subsidiary Bond-Laminates GmbH (Brilon, Germany). Tepex dynalite is used to produce front ends, brake pedals, underbody paneling components, reinforcing structural inserts for body detachable parts as well as carriers for door and electronic modules on a large scale. LANXESS anticipates that the composite material will be used in the future to manufacture backrests and armrests as well as seat shells for new, highly complex seat systems in autonomous driving.

According to Plaggenborg, “We are thinking, for example, of freely rotatable, swivelable or removable seats that not only weigh little but also meet all crash requirements and are fitted with numerous integrated functions such as seat belt, infotainment and comfort systems.”

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Voith unveils digital carbon fiber manufacturing line

Patented production line used to produce the carbon fiber reinforced plastic rear panel for the new Audi A8.

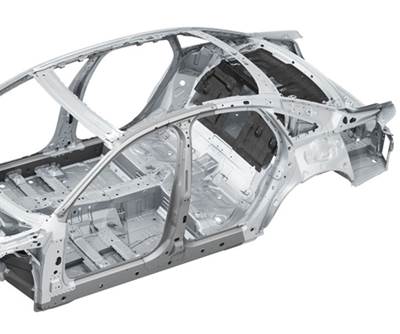

Read MoreMultimaterialism is back in the Audi A8

Audi shares details about the use of carbon fiber composites, steel, aluminum and magnesium in the Audi Space Frame (ASF) for the next-generation A8.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.png;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)