Karl Mayer thermoplastic UD tape production line designed for mass production

The SIM.PLY production line is designed for large-scale production of thermoplastic UD tapes for lightweight structural compone

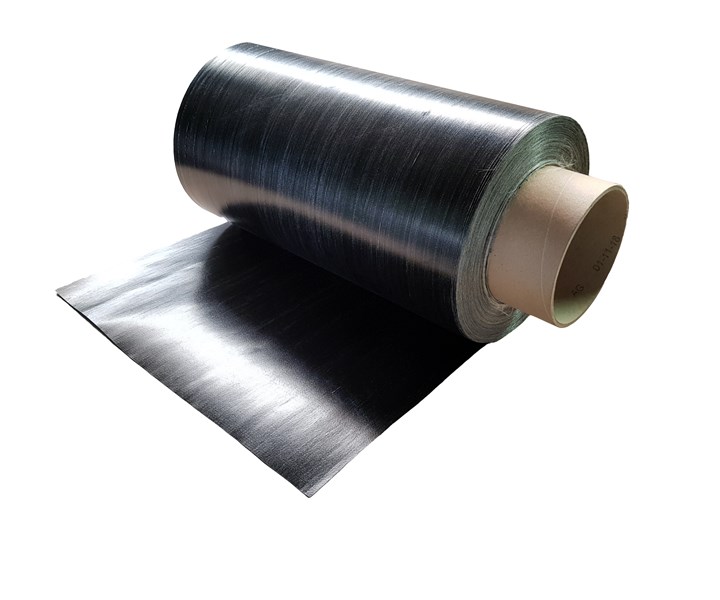

Continuous fiber-reinforced thermoplastic tape made out of glass fiber and polypropylene on Karl Mayer’s SIM.PLY production line. Source | Karl Mayer

Karl Mayer Technische Textilien (Obertshausen, Germany), a specialist in non-crimped fabrics for lightweight structural components, has introduced its latest production line, called SIM.PLY, which produces thermoplastic, unidirectional (UD), fiber-reinforced tapes.

The high-quality tapes, featuring precisely aligned, continuous fibers, are reportedly suitable for use in highly stressed, fiber-reinforced, lightweight structures. The thermoplastic matrix is said to make them easy to process for large-scale production. The SIM.PLY system operates at a high production rate and produces tapes in range of widths.

The company will display this technology at K 2019, Oct. 16-23 in Düsseldorf, Germany.

Related Content

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;width=70;height=70;mode=crop)